For FASH455 class: When writing your blog comment, consider addressing the following aspects:

- Based on the videos, what is your evaluation of the opportunities and challenges of making textiles and apparel in the U.S.?

- In what ways has international trade influenced the growth, decline, or transformation of U.S. textile and apparel production?

- What do you think about the Round House Jeans owner’s strategy of selling imported jeans from Bangladesh at a higher profit margin to “subsidize” its low-margin U.S.-made jeans? Do you think this could be a sustainable business model in the long run?

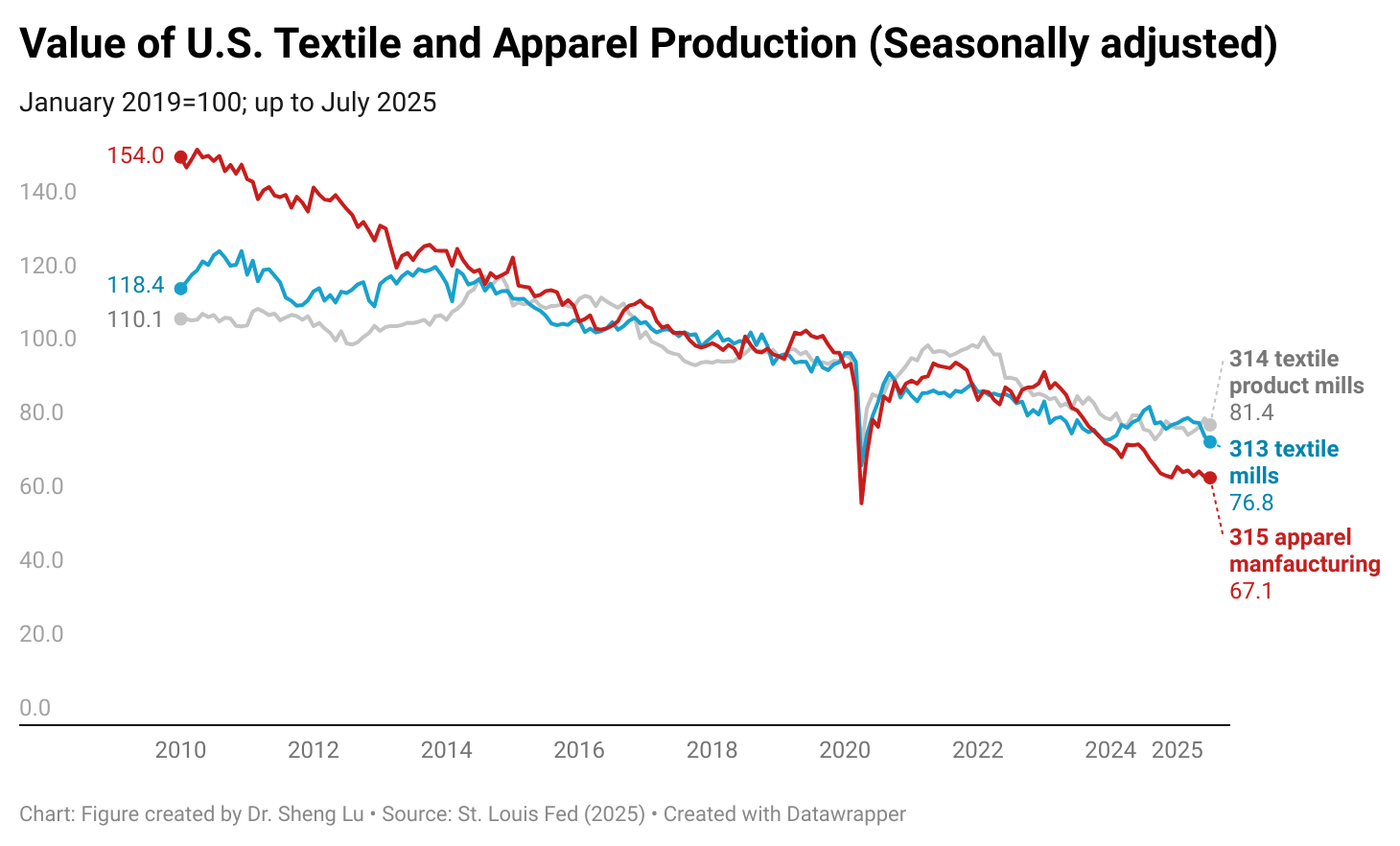

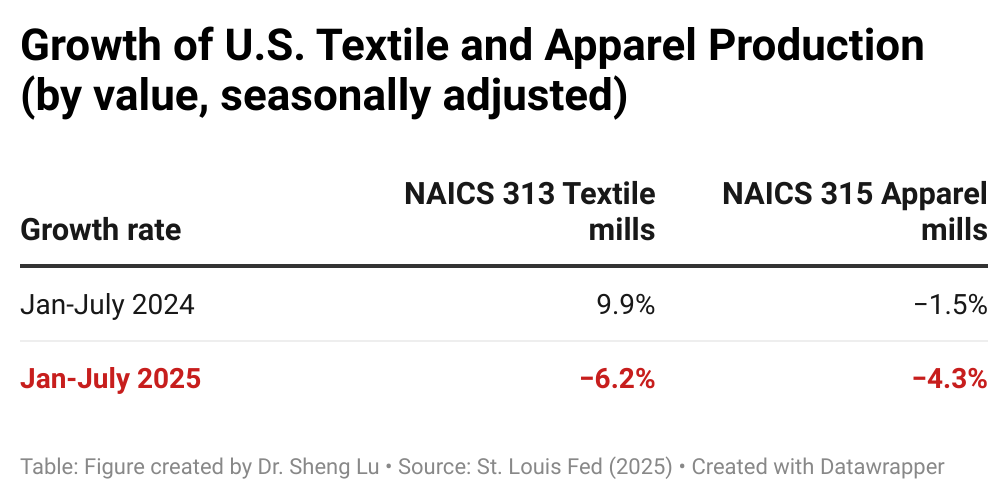

- Based on the videos, why do you think U.S. textile and apparel production experienced even greater losses in the first half of 2025, despite higher tariffs on imports? [Detailed data HERE]

- If you were invited to offer policy recommendations to boost U.S. domestic textile and apparel manufacturing, what would you propose, and why?

Additional reading:

1. Based on the videos, what is your evaluation of the opportunities and challenges of making textiles and apparel in the U.S.?

After watching the videos, it’s clear that there are opportunities for making textiles and apparel in the U.S., but the challenges are honestly pretty huge. One opportunity is that “Made in USA” still has value, and some consumers are willing to pay more for it. Plus, advanced technology and automation can help bring some production back by lowering labor needs. But the biggest challenge is still labor cost. U.S. factories can’t compete with countries that have way cheaper labor. Finding skilled workers is also becoming harder. So overall, it’s possible to do U.S. production, but it has to be super specialized or use a lot of tech to survive.

2. What do you think about the Round House Jeans owner’s strategy of selling imported jeans from Bangladesh at a higher profit margin to “subsidize” its low-margin U.S.-made jeans? Do you think this could be a sustainable business model long term?

Honestly, I get why the owner is doing it, because U.S. made jeans are expensive to make and probably wouldn’t survive without some extra money coming in. But long term, I’m not sure how sustainable it is. If the company relies too much on imported jeans to keep the U.S. production alive, then any change in tariffs, shipping costs, or supply chain issues could mess up the whole model. Also, if consumers decide they only want the cheaper imported jeans, the U.S. made ones might not sell enough to justify keeping production here. It feels like a temporary solution rather than something that can hold up for years unless the company finds a way to make U.S. production more profitable on its own.

1. The videos prove that the US is advanced in technology and automation. Made in the USA branding helps industries compete, because consumers value that. But, a major challenge of domestic apparel production is high costs, small-scale manufacturing and skill gaps in the workplace. In general, the US can produce domestically – but small businesses or batch manufacturing will perform best over mass production.

2. International trade has shifted apparel production offshore. Many domestic factories and jobs were lost due to this. Global trade has pushed the US to produce more advanced materials, textiles and technologies rather than apparel. This aligns with the US’s capitals-based system in using our advanced technologies to our advantage. US textile exports remains competitive while we focus on apparel imports.

1. As mentioned in the video, since there is essentially nowhere in America to gain manufacturing experience, when manufacturers hire people, they are starting from scratch. It can take up to years to train just one individual– this means more time, money, and effort spent on things they used to not have to. On the other hand, in order to make profit at all, it is still essential for Run House Jeans to have at least some of their jeans sewn outside of the US, in this case, in Bangladesh.

Jeff Bowan explains how with the higher tariffs, people are not placing orders because they are unsure of what the ultimate price will be– this is mainly happening in places like China, who are getting hit hardest with the tariffs. Furthermore, Bowan explains how he has been the one “eating” the tariffs– while Trump may have intended for other countries to face the repercussions of the tariffs, ultimately, America faces the same repercussions. It falls on US companies, the economy, and the consumer.

2. International trade has greatly reshaped U.S. textile and apparel production. As trade barriers have fallen and low-cost countries enter the global market, many U.S. apparel companies offshored manufacturing in order to reduce labor costs, leading to a major decline in domestic manufacturing and production. However, U.S. production has shifted towards textiles making which is supported by advanced technology and automation. Furthermore, trade agreements also encouraged regional supply chains, where U.S. mills produce yarns and fabrics that are put together abroad and re-imported. Overall, I would argue that international trade has caused a decline in basic apparel manufacturing in the U.S., but has also created windows for innovation and more efficient production in the U.S.