About the factory

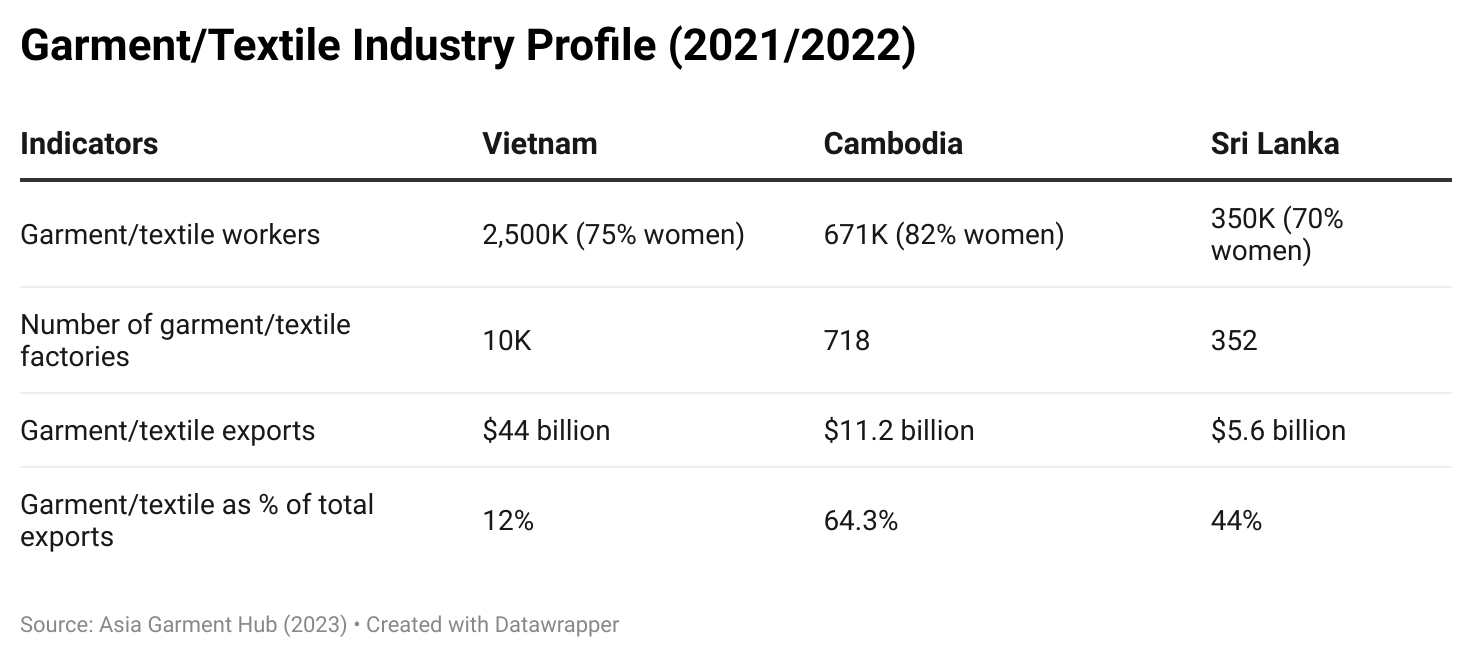

- The factory is a foreign direct investment (FDI) operation in central Vietnam specializing in ODM (Original Design Manufacturing) — producing ready-made designs that can be customized for private labels. Specific products include sportswear, casual wear, workwear, and uniforms.

- The factory hires about 500 workers, and it aims to increase the size to 700-1000 workers, which was the pre-COVID level. The monthly pay averaged about $400.

- The garment factory mainly exports to the U.S., Europe, and Brazil. The factory can do both full package sourcing (i.e., manages the entire production process, from procuring materials to manufacturing, quality control, and packaging—delivering finished goods ready for export) and CMT sourcing (i.e., cut make and trim–buyer provides the materials and designs, while the supplier only performs garment assembly, sewing, and finishing).

- The factory mostly uses woven fabrics, and they are mainly sourced from China and Europe. Other sources include Taiwan, Thailand, and Malaysia. Some fabrics are Oeko-Tex certified, given the growing importance of using sustainable materials.

- To meet the rules of origin requirements under free trade agreements (FTAs), such as the EU-Vietnam FTA, Vietnam is making efforts to enhance its local textile manufacturing capability.

- To meet the clients’ needs, the factory has received several certifications related to social compliance and sustainability, including WRAP, BSCI, and ISO 9000.

- Textile waste is partly sold or donated (e.g., blankets and jackets for local communities).

For FASH455 class: When writing your blog comment, consider addressing the following aspects:

- How does the video help you understand the complexity of apparel sourcing?

- Based on the video, what is your evaluation of the strengths of the factory as an apparel sourcing base for US fashion companies? Any specific area in which the factory can be improved?

- If you have the chance to visit a garment factory, what would you focus on evaluating and why?

Additional reading: Vietnam overtakes China as US’s top apparel supplier (FDi intelligence, Financial Times, October 8, 2025)