ASKET is a prominent online retailer based in Sweden that commits to complete supply chain transparency. Based on analyzing nearly 40 unique products and their detailed supply chain information posted on ASKET’s website as of May 2023, the article aims to shed light on the company’s supply chain traceability progress and the remaining challenges it faces.

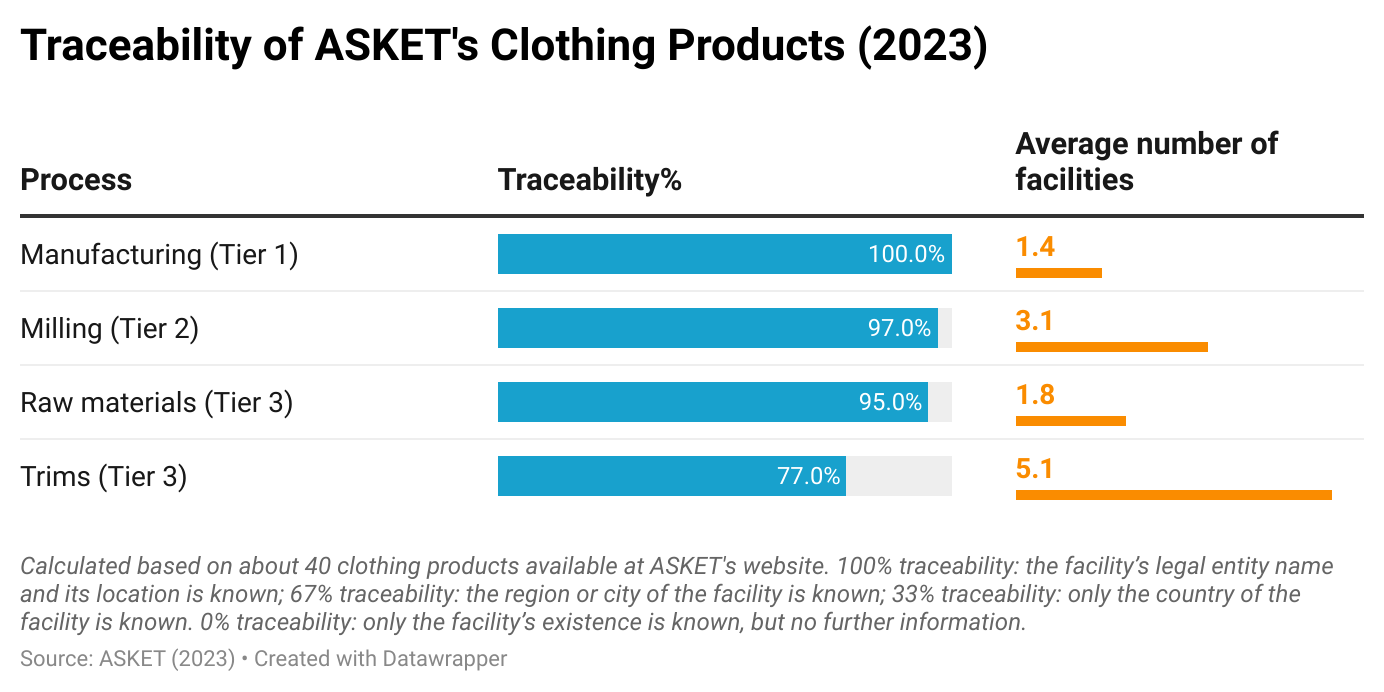

First, while ASKET achieved full traceability for Tier 1 suppliers, tracking Tier 2 and Tier 3 suppliers was more difficult. For example, compared with its perfect traceability score for Tier 1 suppliers (i.e., garment factories), ASKET’s average traceability for Tier 2 Milling factories (i.e., yarn and fabric producers) was at around 97%, and the score fell to only 77% for trims suppliers in Tier 3.

As one critical contributing factor to the phenomenon, Tier 2 and Tier 3 suppliers had far more players than Tier 1, which presented a more significant challenge in obtaining detailed information about all the factories involved. For example, ASKET’s garment cutting and sewing operations predominantly occurred within a single facility. In contrast, making yarns, fabrics, and trims EACH usually involve multiple facilities in different parts of the world.

Second, a comprehensive understanding of the sub-supply chains associated with apparel components is pivotal in enhancing a fashion company’s overall traceability. Notably, the apparel supply chain is far more complicated than the commonly known four stages—fiber, yarn, fabric, and garment manufacturing. Rather, apparel components like yarns, fabrics, sewing threads, buttons, and zippers have complex and intricate sub-supply chains. For instance, for ASKET’s shirts or polo shirts:

- Cotton was “farmed in New Mexico, Arizona, California and Texas, USA, ginned in Anqing, China.”

- Yarn was “spun and twisted in Hyderabad, India,” and “dyed in Varese, Italy.”

- Fabric was “woven in Letohrad, Czech Republic, dyed and finished in Prato, Italy.”

- Sewing thread was “produced in Breisgau, Germany, wound and packed in St. Maria de Palautordera, Spain”

- Button was produced in Saccolongon, Italy, with corozo farmed in Manabi, Ecuador.

Third, using recycled textile materials in apparel products could make it trickier to map the supply chain.

- ASKET reported no problem tracking recycled textile materials derived from natural fibers, especially recycled wool products.

- ASKET’s capability of tracing recycled man-made fiber textiles yielded mixed results. For example, ASKET was still investigating the Tier 3 raw material suppliers for one fabric made with “100% pre-consumer recycled nylon.” Likewise, for one body fabric derived from “plastic waste collected from Spanish Mediterranean and French Atlantic oceans and coastlines,” pinpointing the precise origin of the raw fiber posed a challenge.

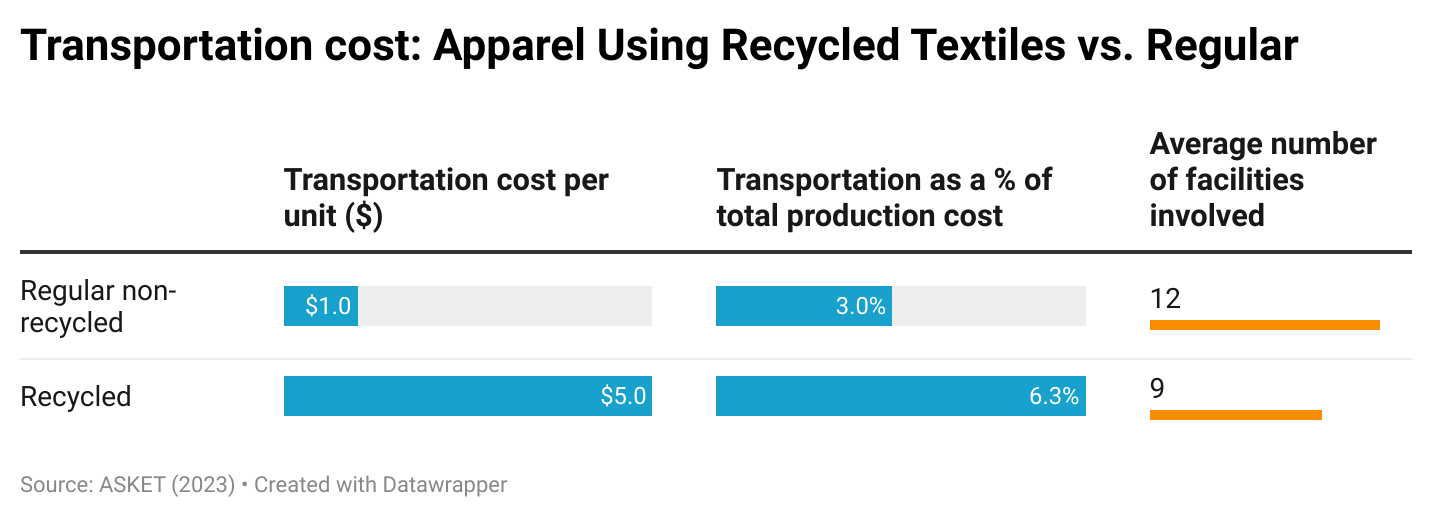

Fourth, ASKET’s data shows that using recycled textiles in apparel products could incur higher transportation costs. For example, the average transportation cost for an ASKET garment using recycled textiles would reach $5 per unit (or 6.3% of the total production costs), much higher than regular clothing using non-recycled materials ($1 per unit or 3% of the total production). However, on average, making a garment using recycled textile materials could involve fewer facilities(e.g., 9 vs. 12). This result suggests that the higher transportation cost associated with clothing made from recycled textiles may not be attributed to a longer supply chain but rather to a more tedious and expensive recycled fiber collection process.

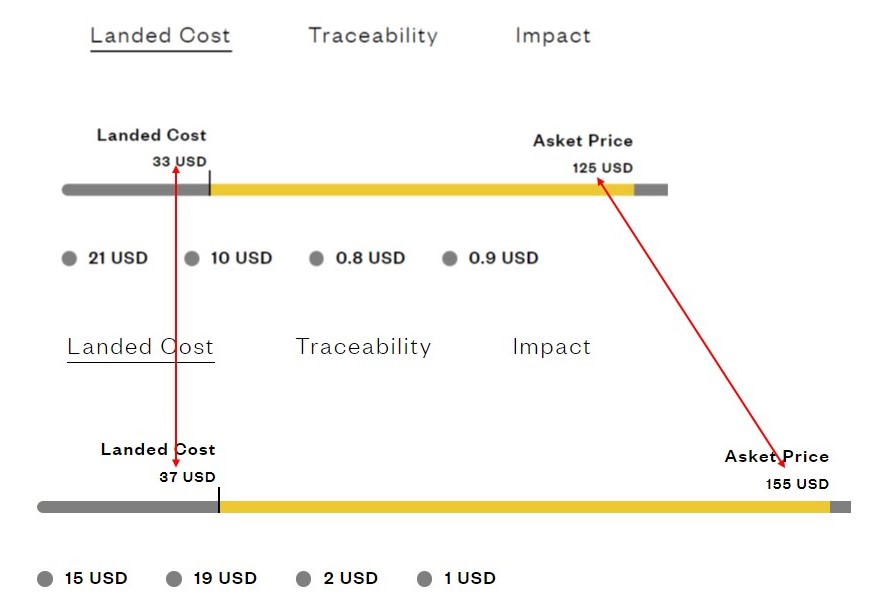

Additionally, ASKET’s data indicates a strong correlation between its retail price and sourcing costs. Specifically, ASKET’s applied a gross margin% ranging from 71%–81%. This implies that a $2 increase in sourcing costs could potentially lead to a retail price increase of $10-$20. Thus, controlling and managing sourcing costs will always be a priority for a fashion company.

By Sheng Lu

Further reading: Lu, Sheng (2023). How Asket is achieving apparel supply chain traceability. Just-Style.