In a new Just-Style mini series, students from FASH455 and the FASH department at the University of Delaware shared their valuable Gen Z perspectives on the impact of the recent tariff increases.

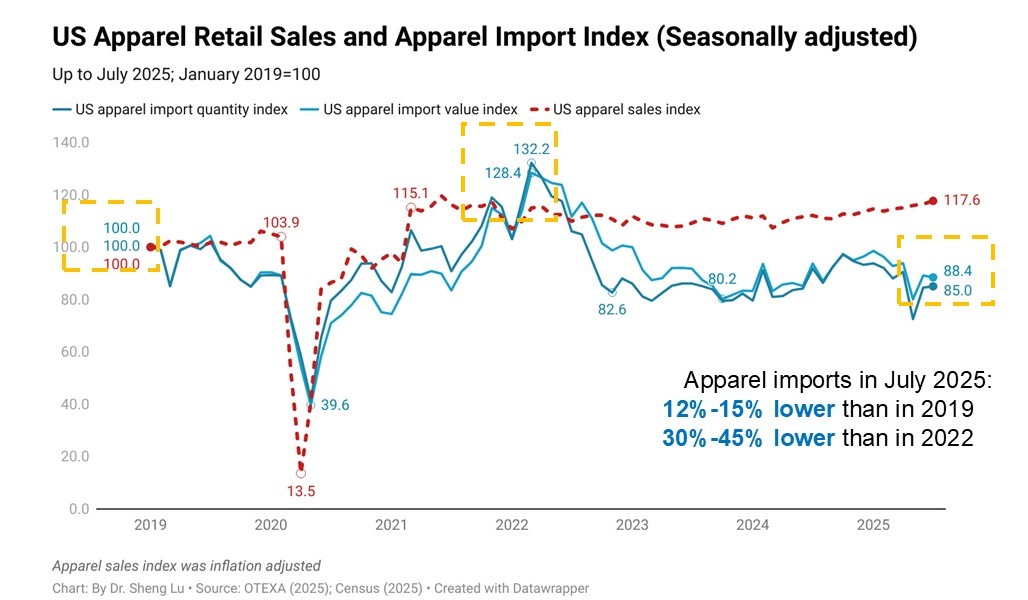

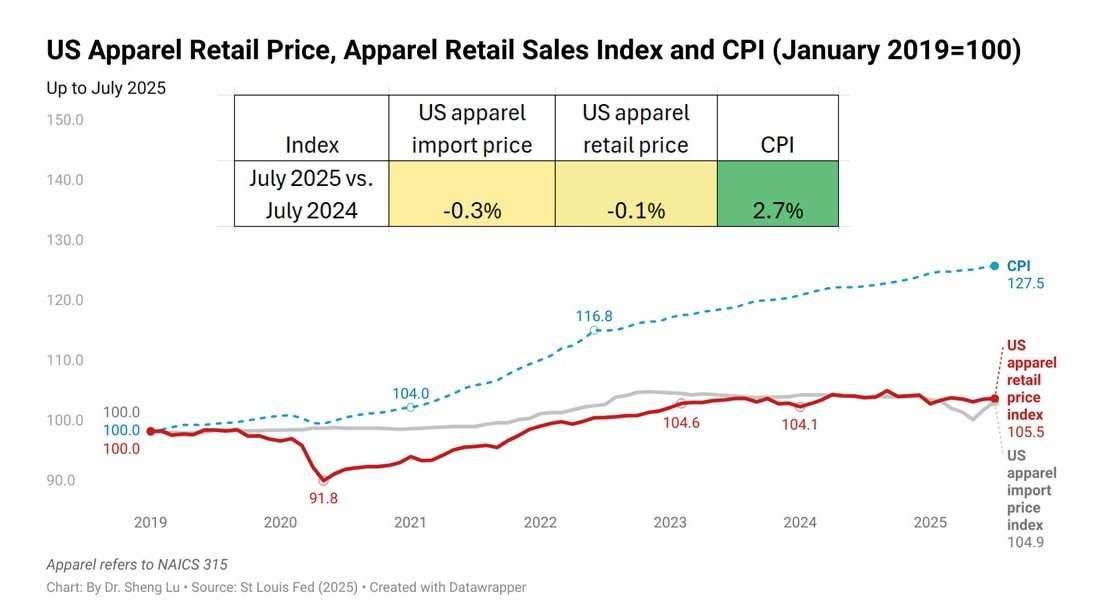

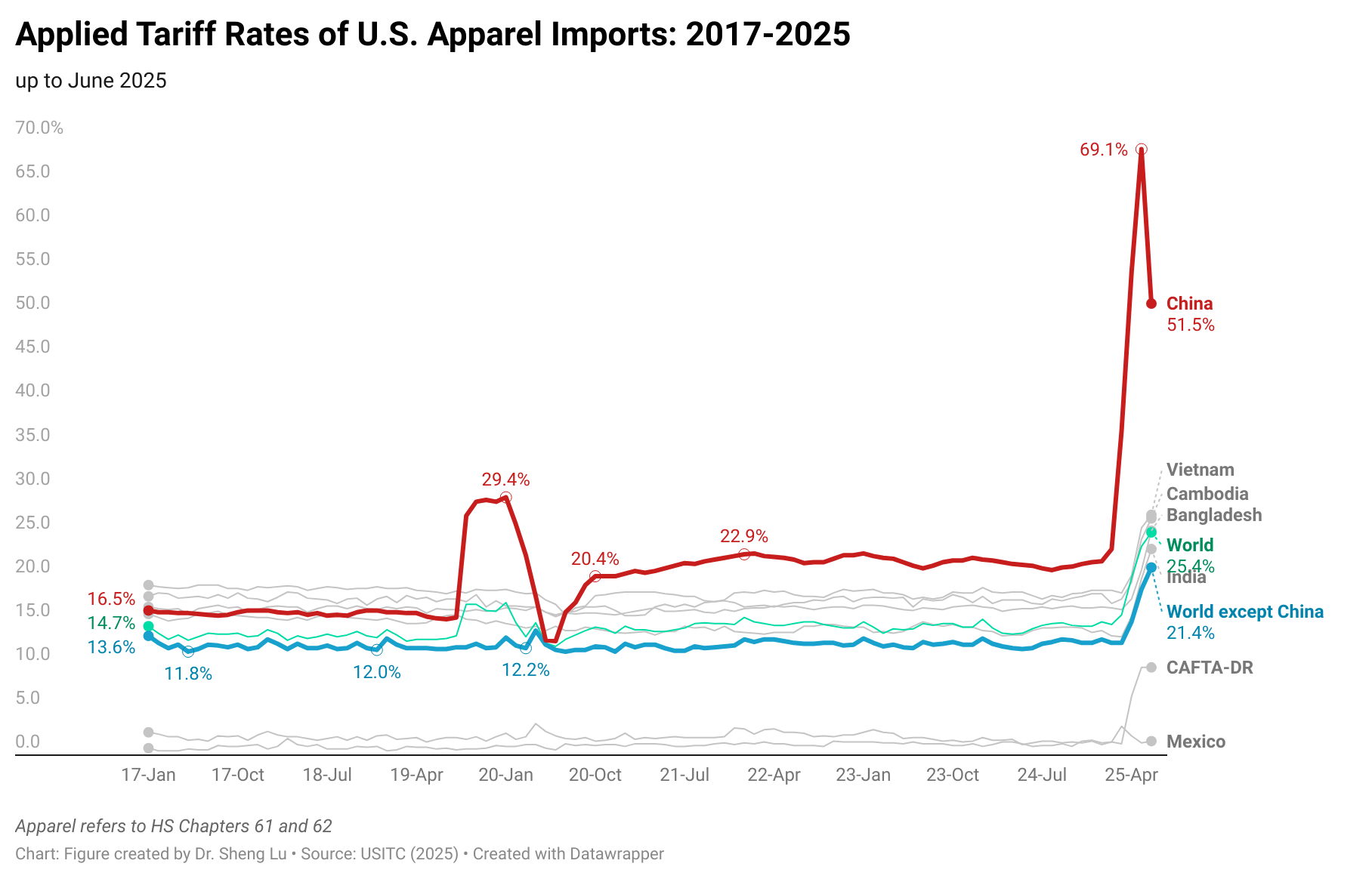

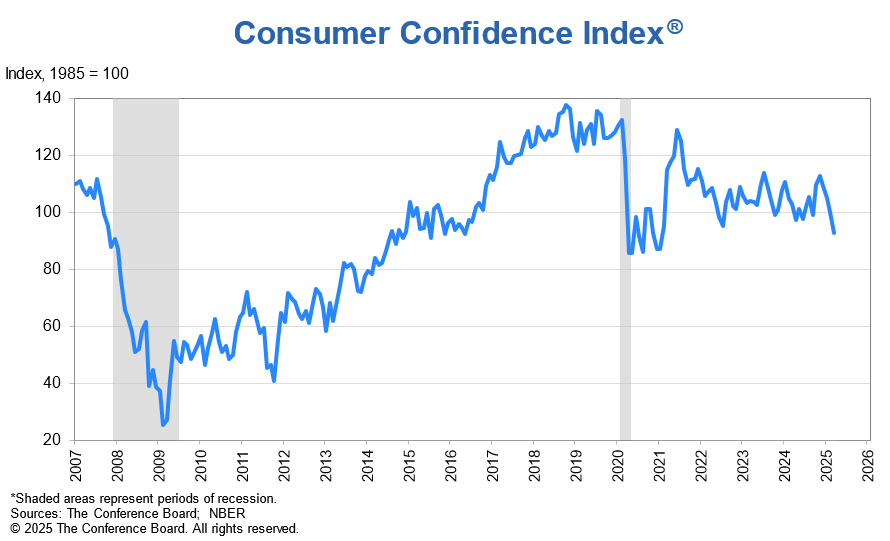

Students’ responses reveal that the impacts of the tariff increase on ordinary U.S. consumers are real, direct, and significant. Like other consumer groups, our Gen Z students express deep concern about the adverse effects of tariffs on the U.S. economy, market uncertainties, and the fashion industry’s growth prospects this year. While shopping for clothing, many students have noticed price increases and reduced product availability due to tariff hikes and related disruptions.

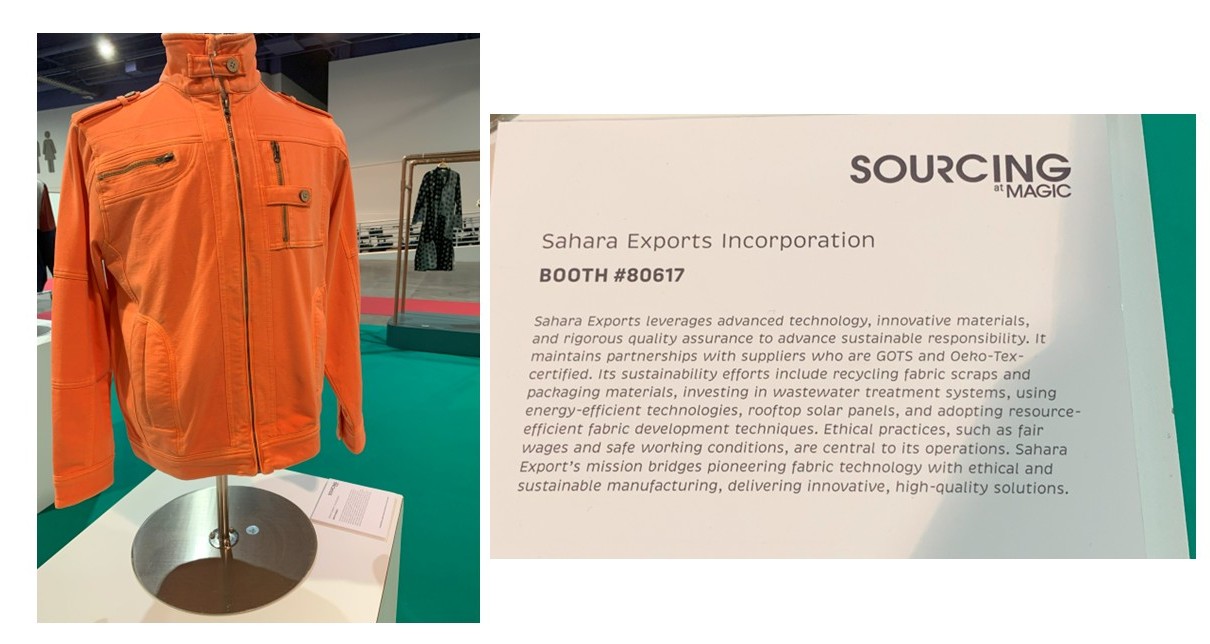

On the other hand, as Gen Z consumers, students send a strong message to fashion brands and retailers—sustainability still matters. In fact, in this environment, students have become ever more conscious of sustainability, asking critical questions such as: Do I really need to buy more clothing? Where was the clothing made? Was the clothing produced ethically? In other words, we may see a growing shift toward “slow fashion” among Gen Z consumers, who expect apparel brands and retailers to make even stronger commitments toward sustainability and social responsibility, instead of compromising these values for “cost mitigation.”

Likewise, students expect higher-quality products or items that can last longer to justify the higher price they pay. Regularly shopping for secondhand clothing, driven by its affordability, environmental benefits, and unique styles, could also become increasingly popular. This leaves an interesting question about the future of cheap but low-quality fast fashion and its attractiveness among Gen Z consumers.

The mini series is available through Just-style. Below are selected comments from students:

Gen Z consumers care about tariffs in the news

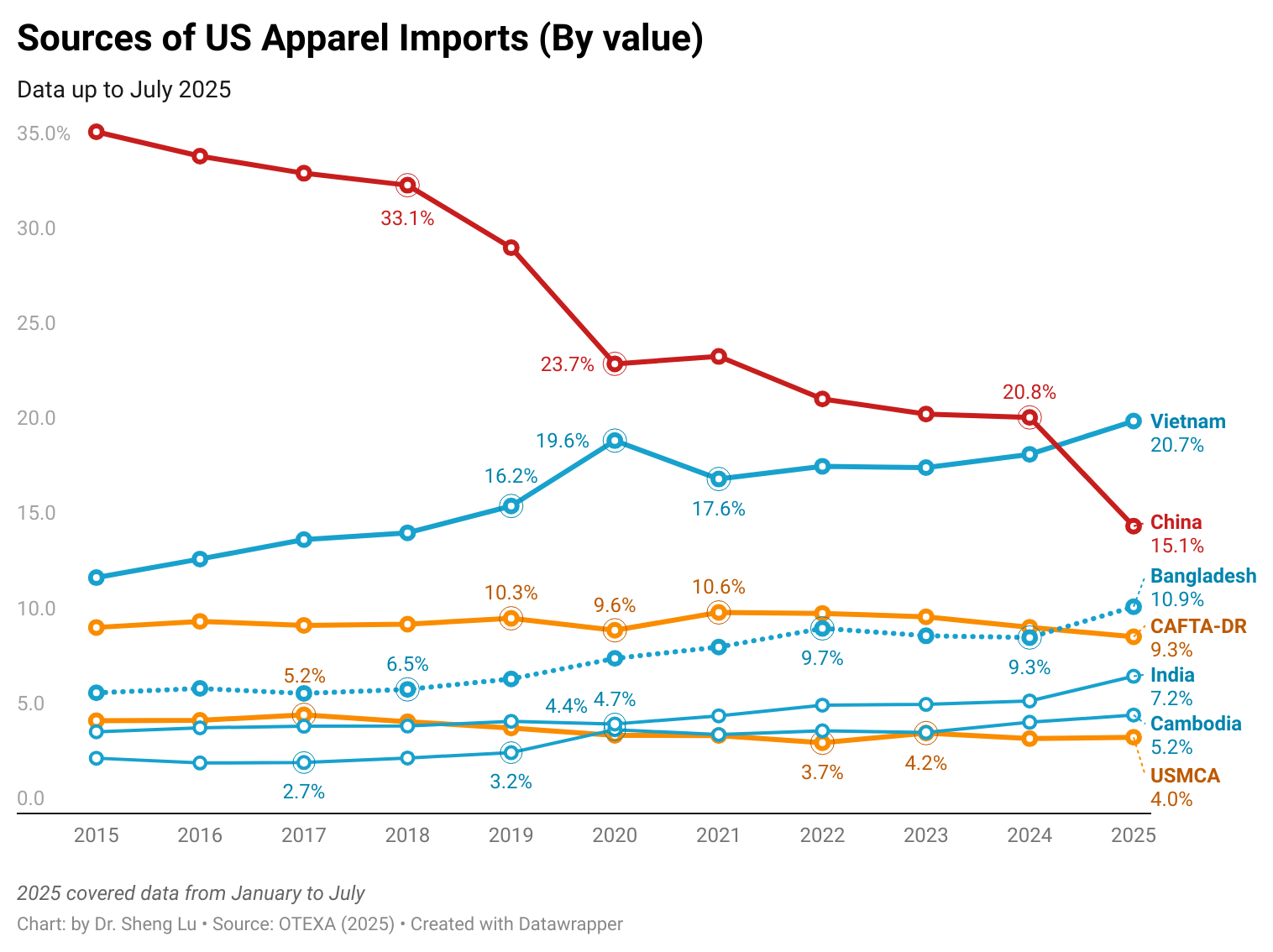

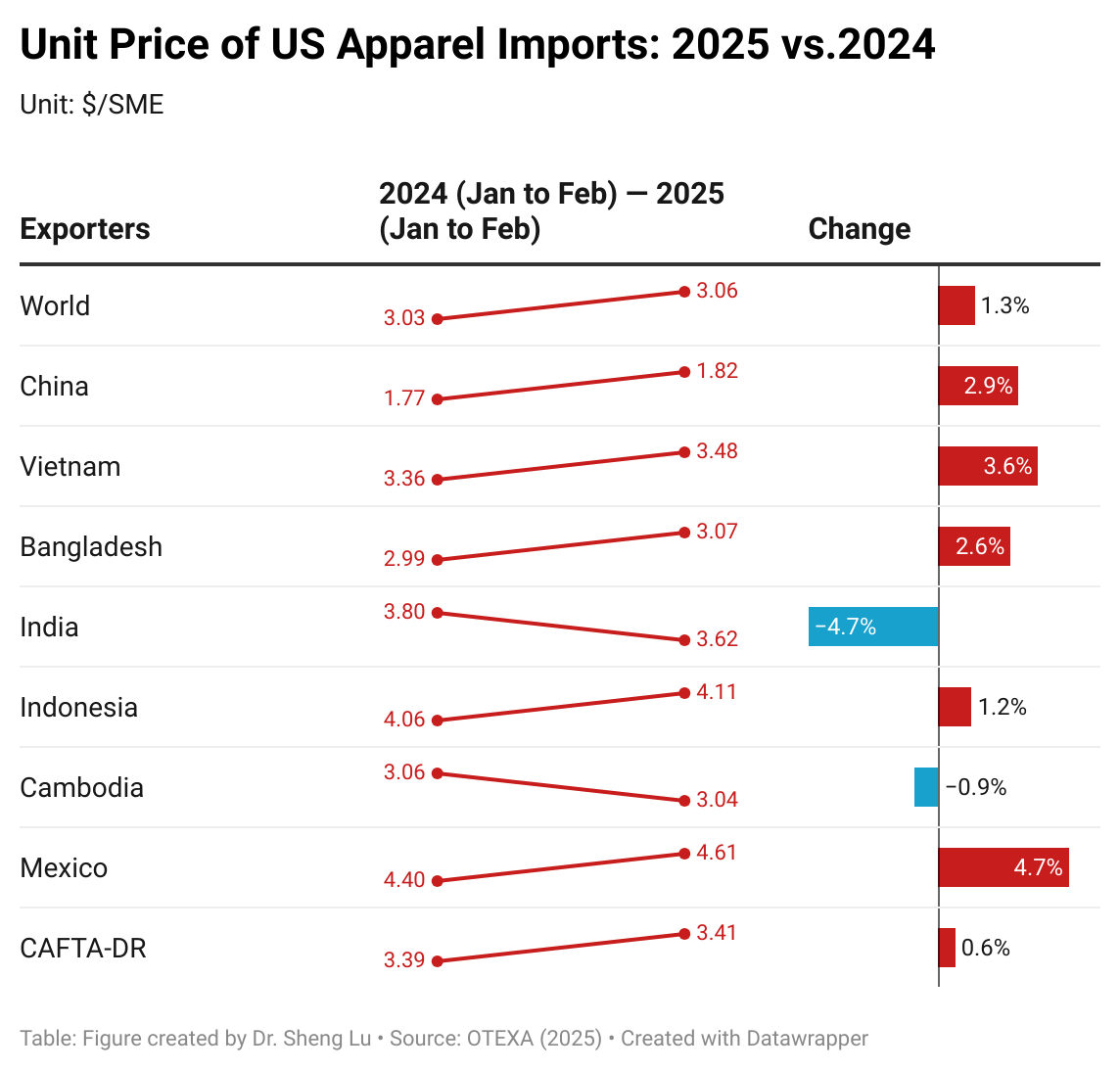

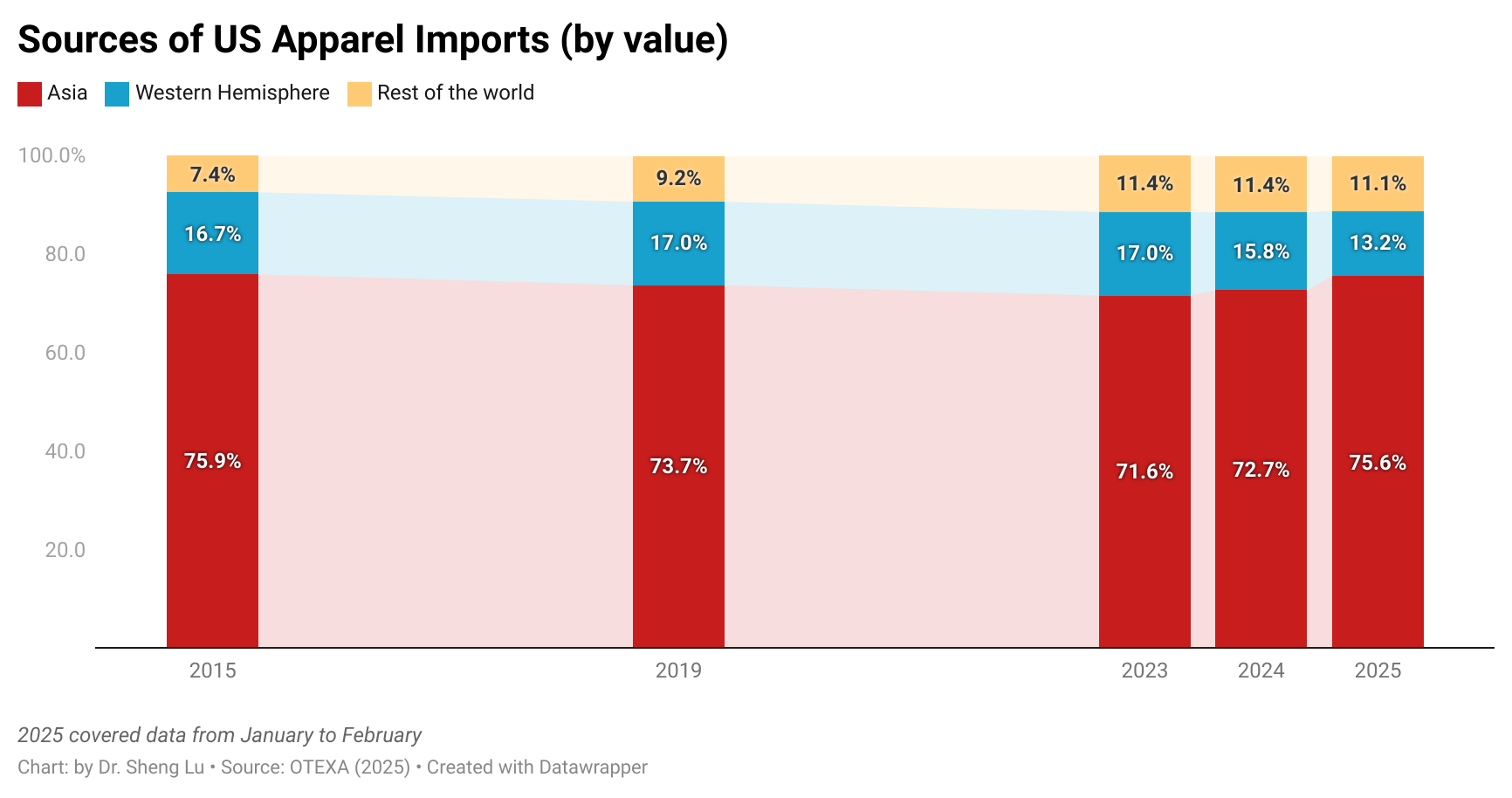

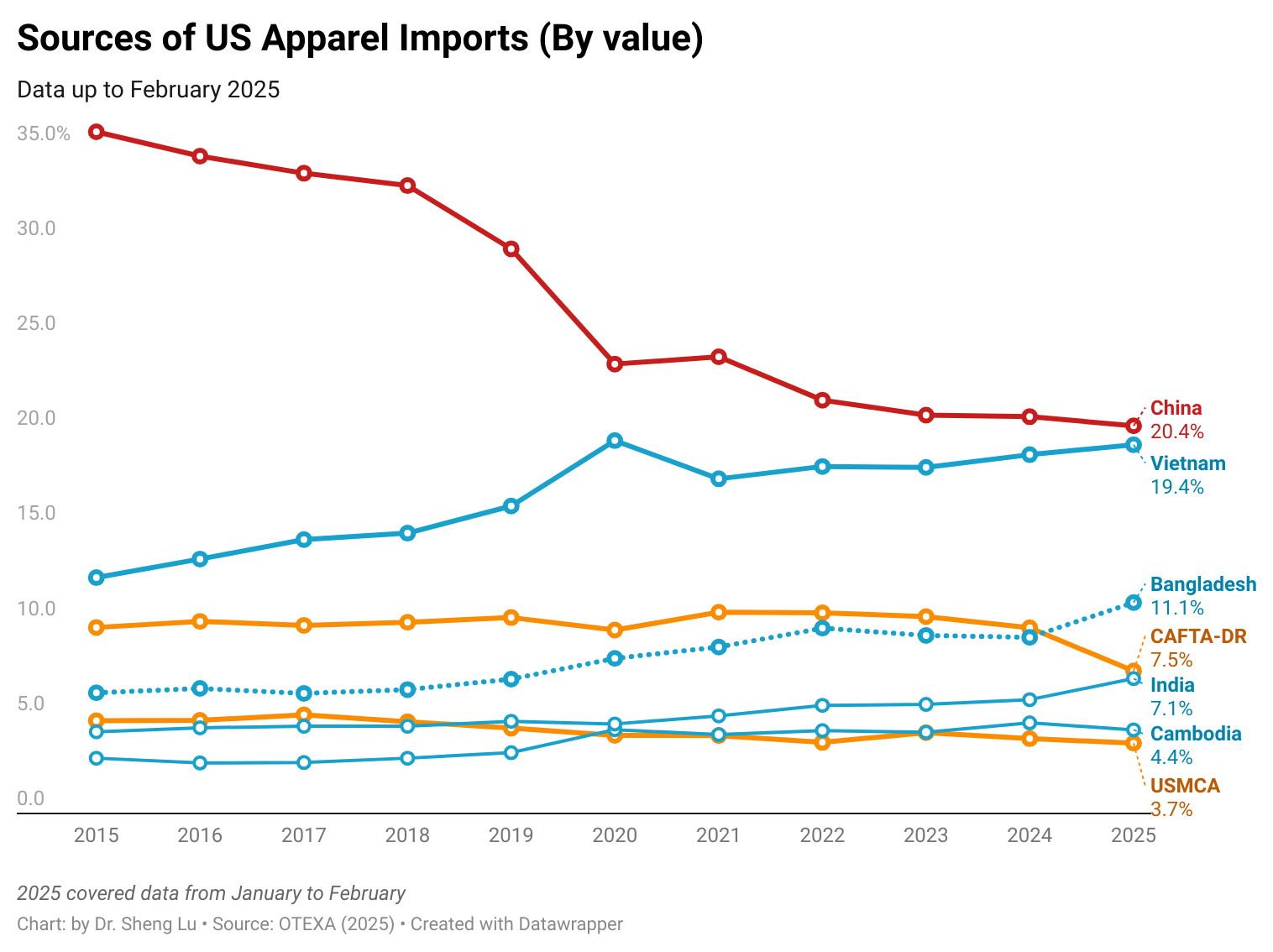

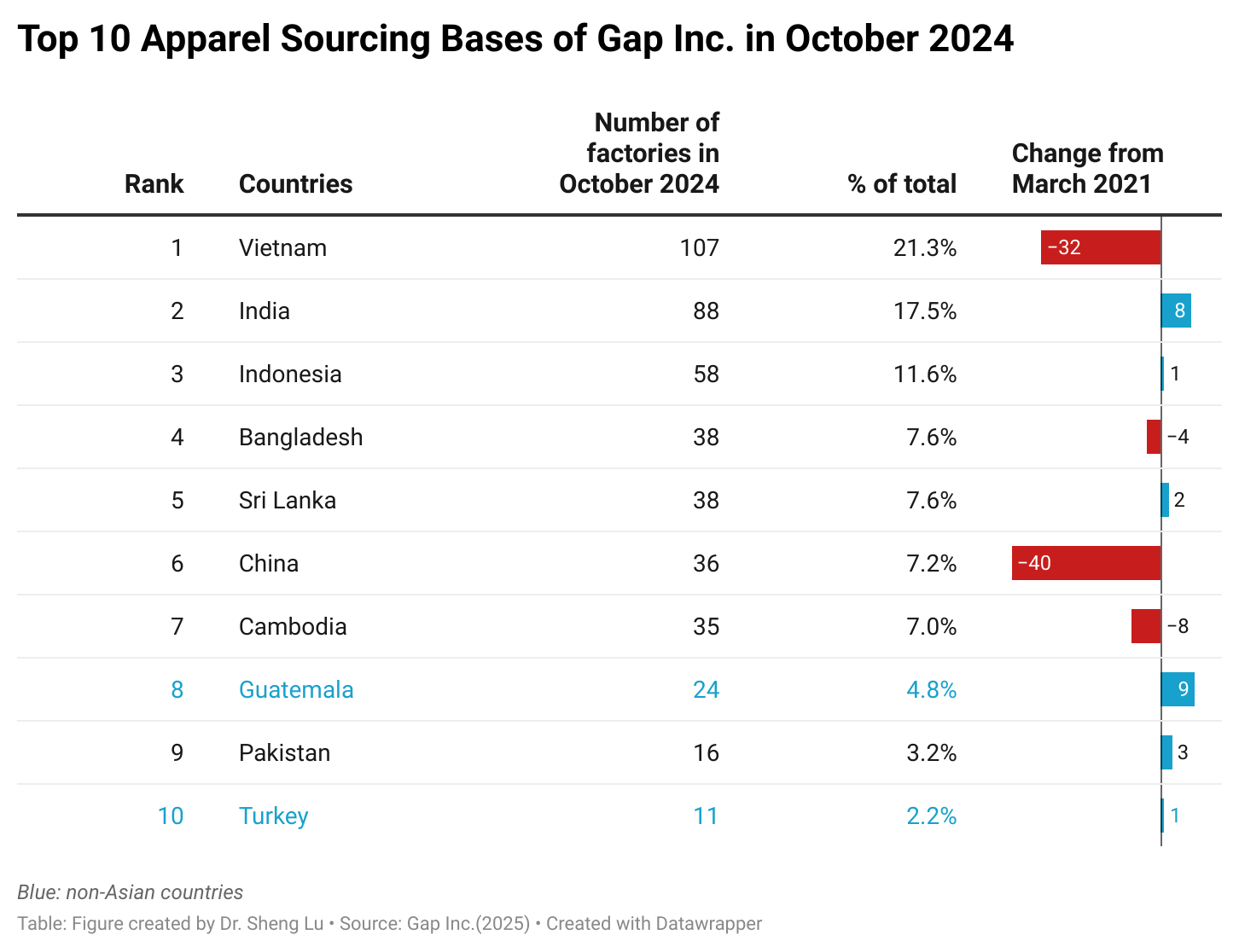

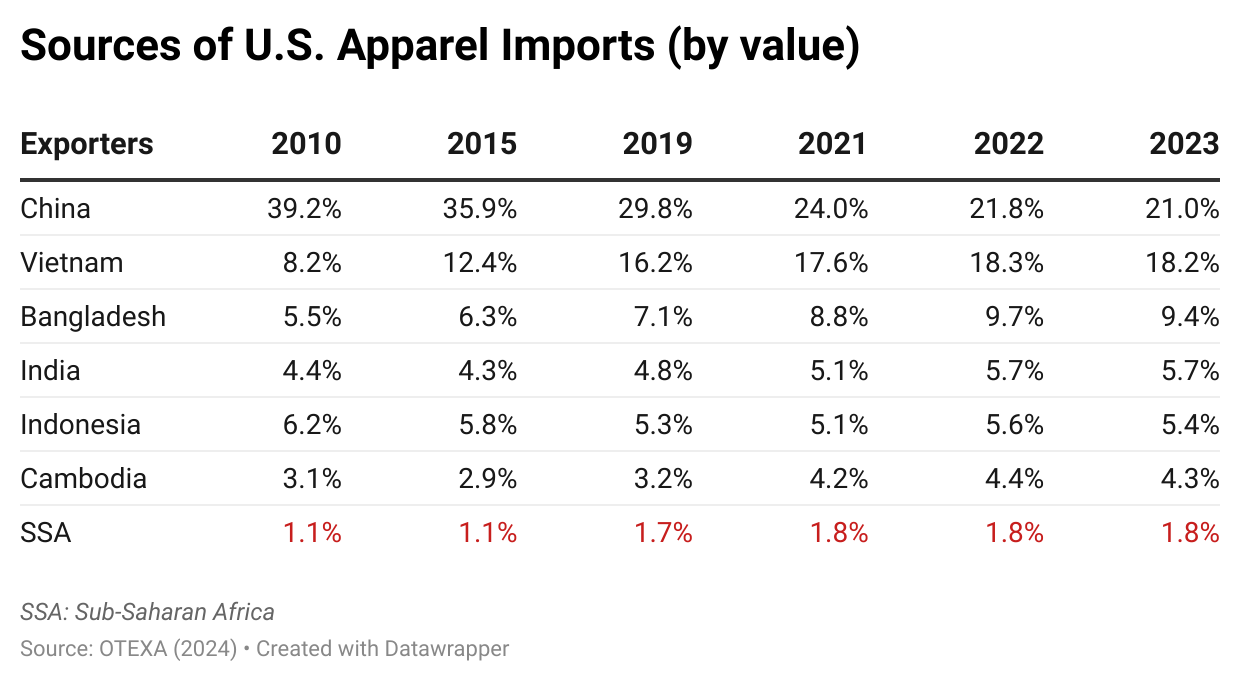

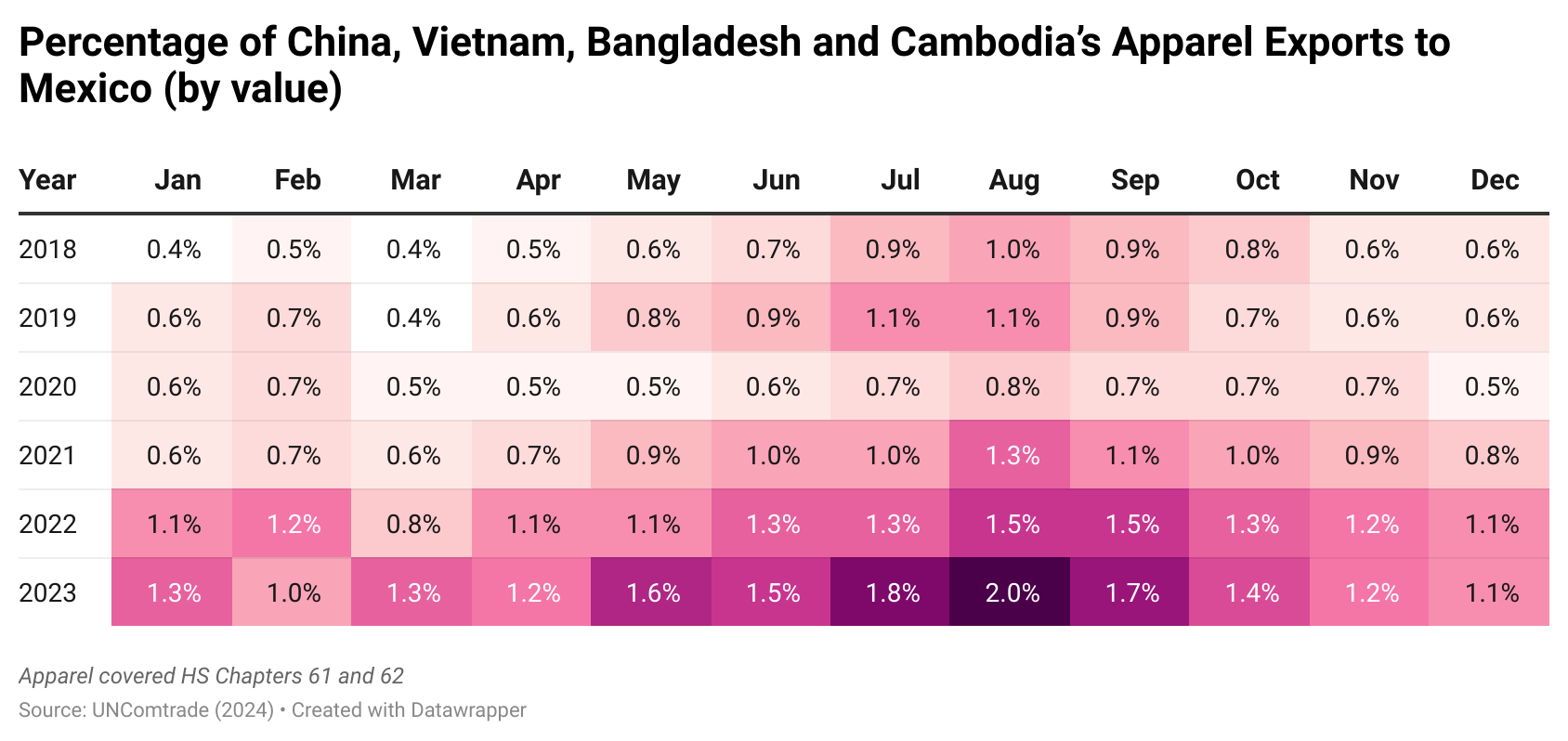

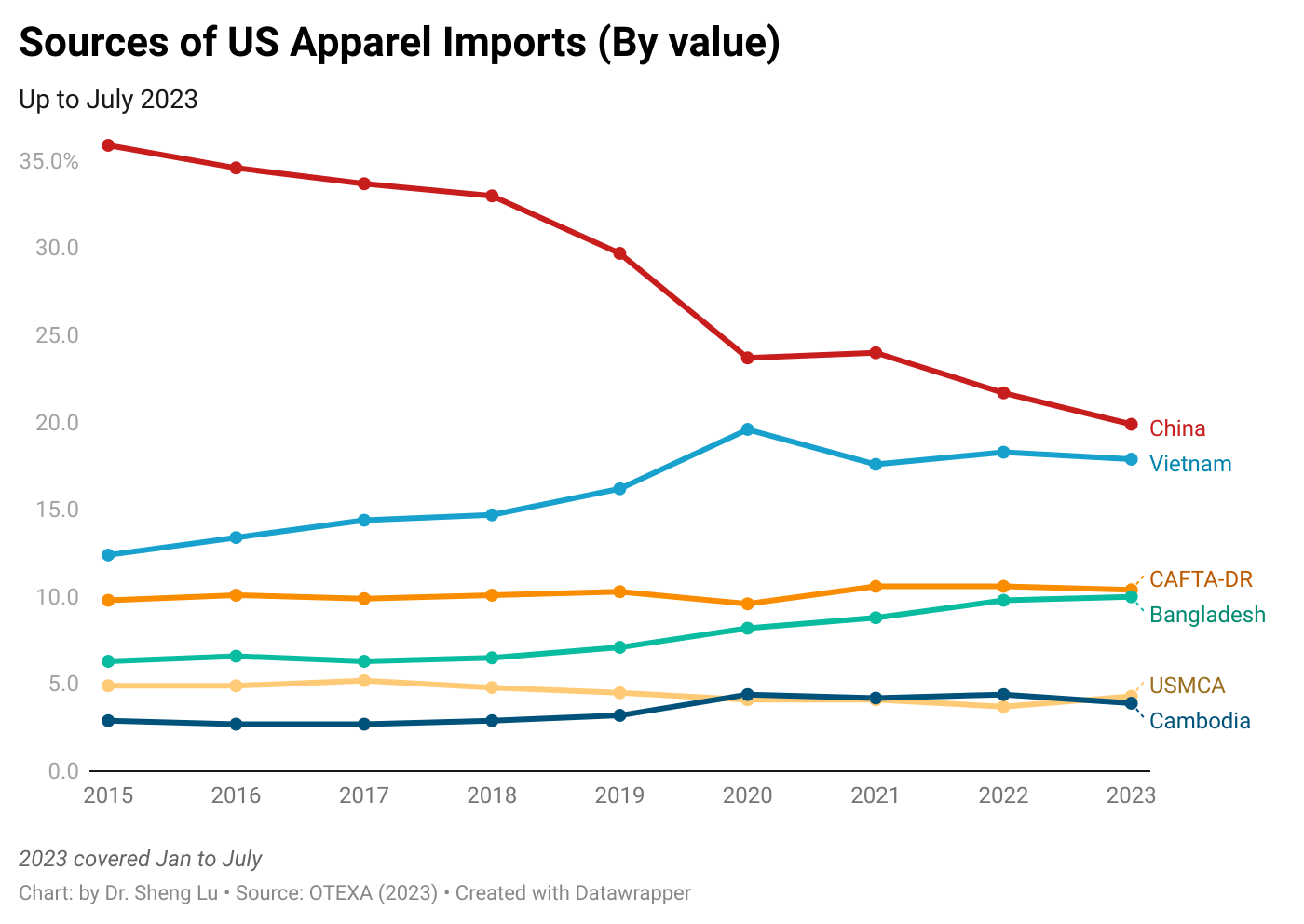

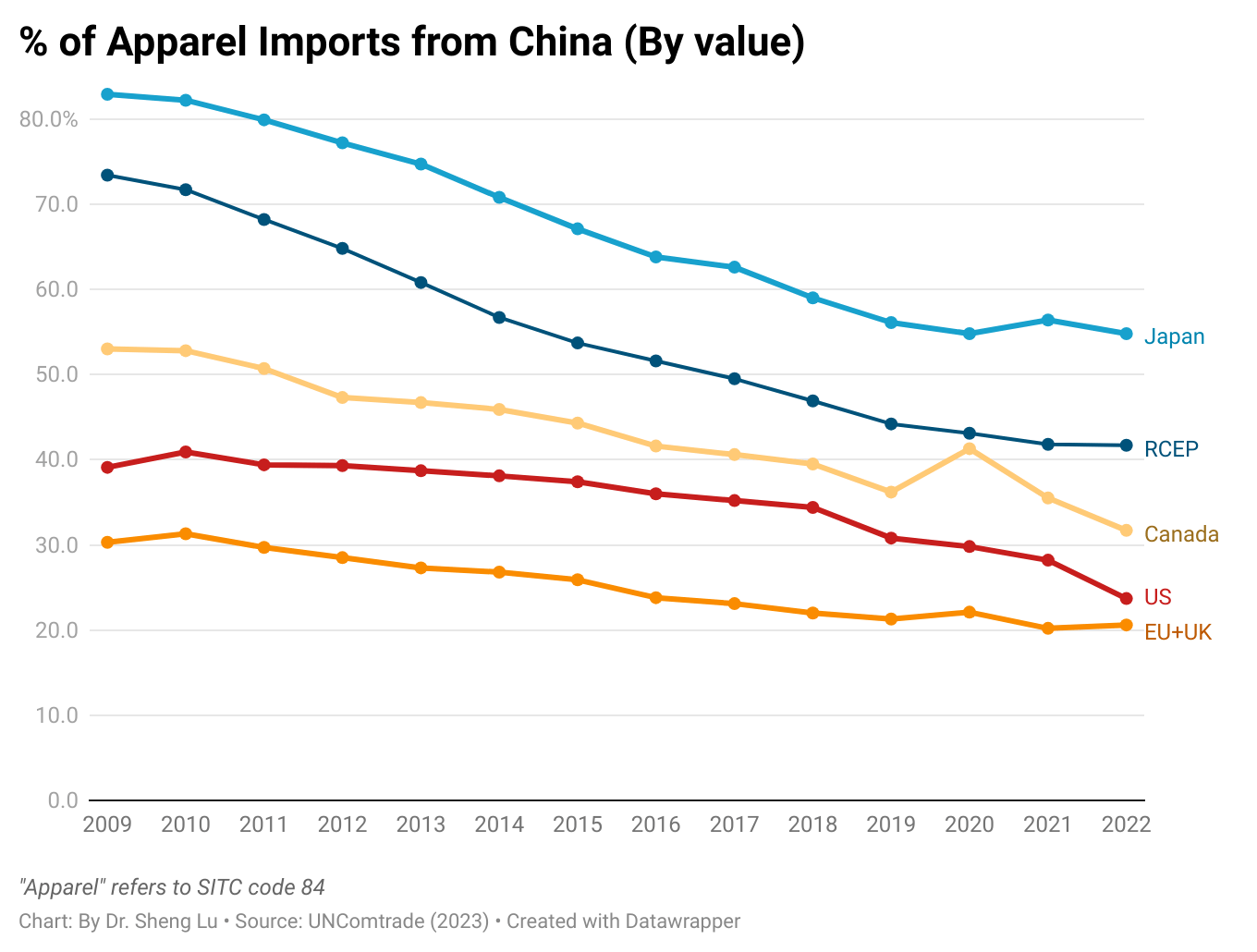

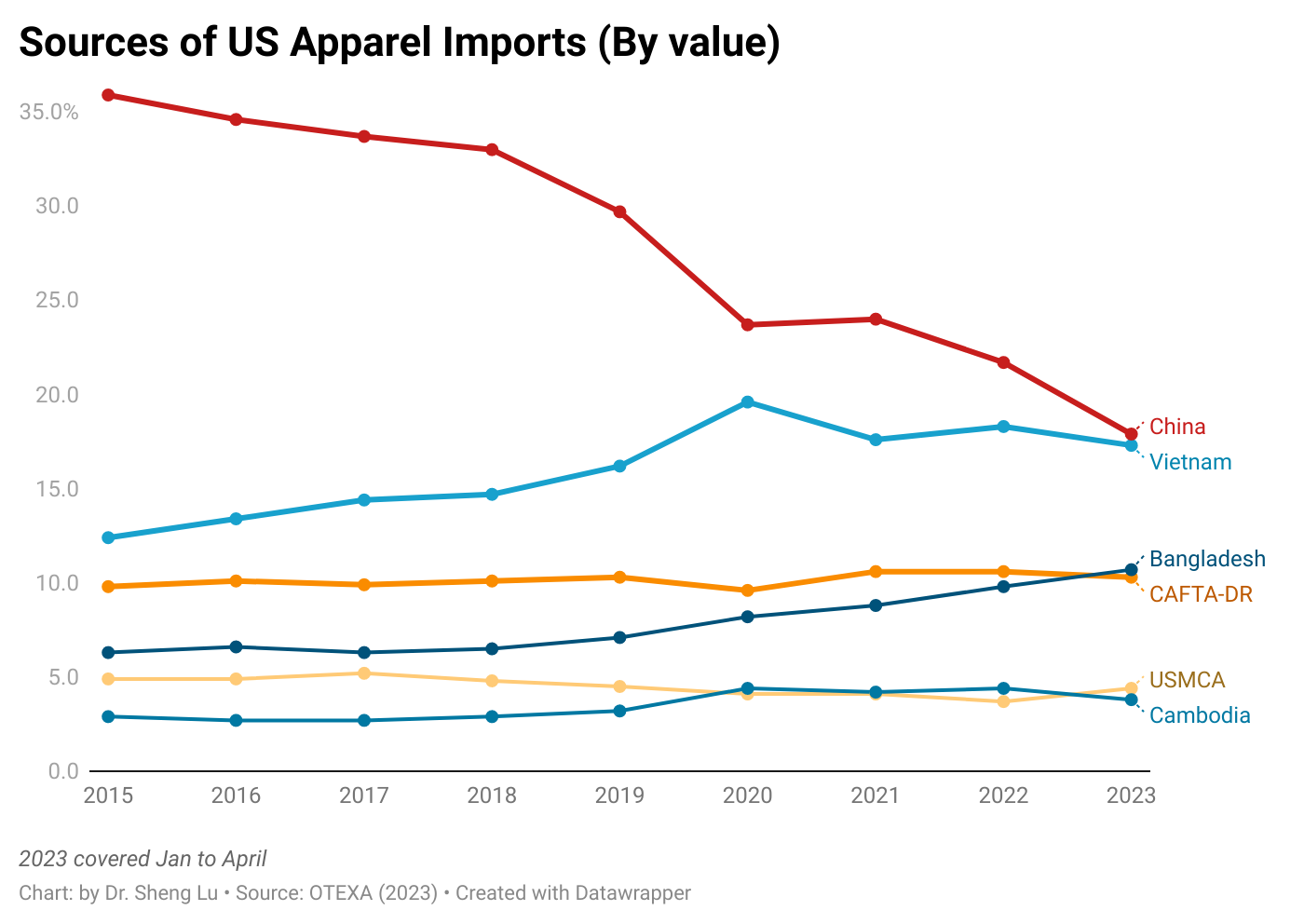

Rachel Zemel (Fashion Merchandising and Management major): As a Fashion Merchandising and Management major, I’ve definitely been paying closer attention to how tariffs impact what we see on the sales floor. Learning about global sourcing and trade agreements in class has made me more curious about where products are coming from and how political or economic shifts can directly affect the retail industry. I’ve caught myself checking clothing labels more often to see where things are made and understand why certain brands are shifting their production away from countries like China. I think what used to feel like a distant conversation now feels very connected to the way I shop and think about product availability.

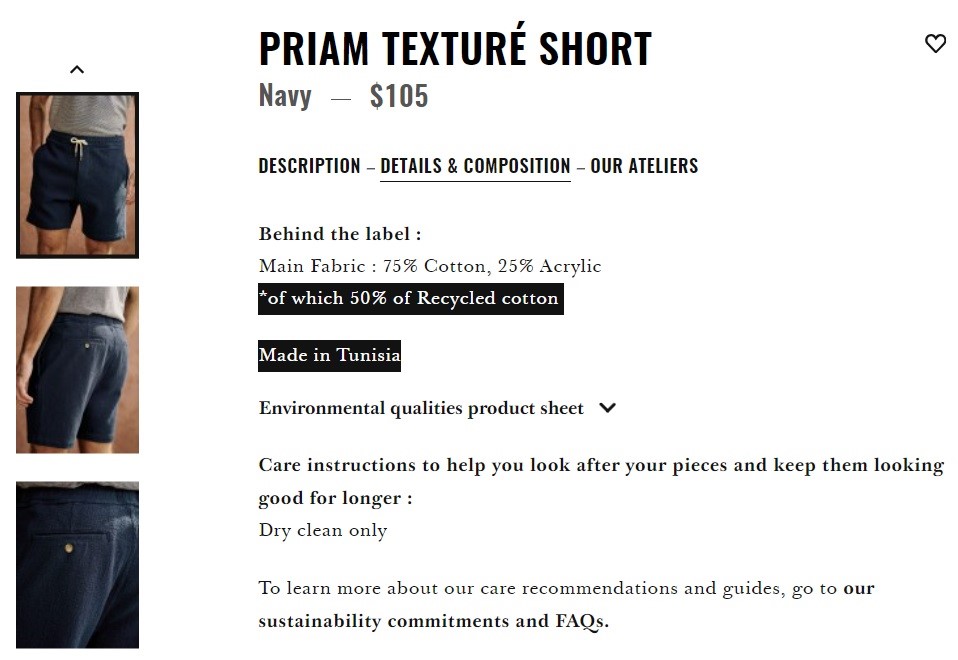

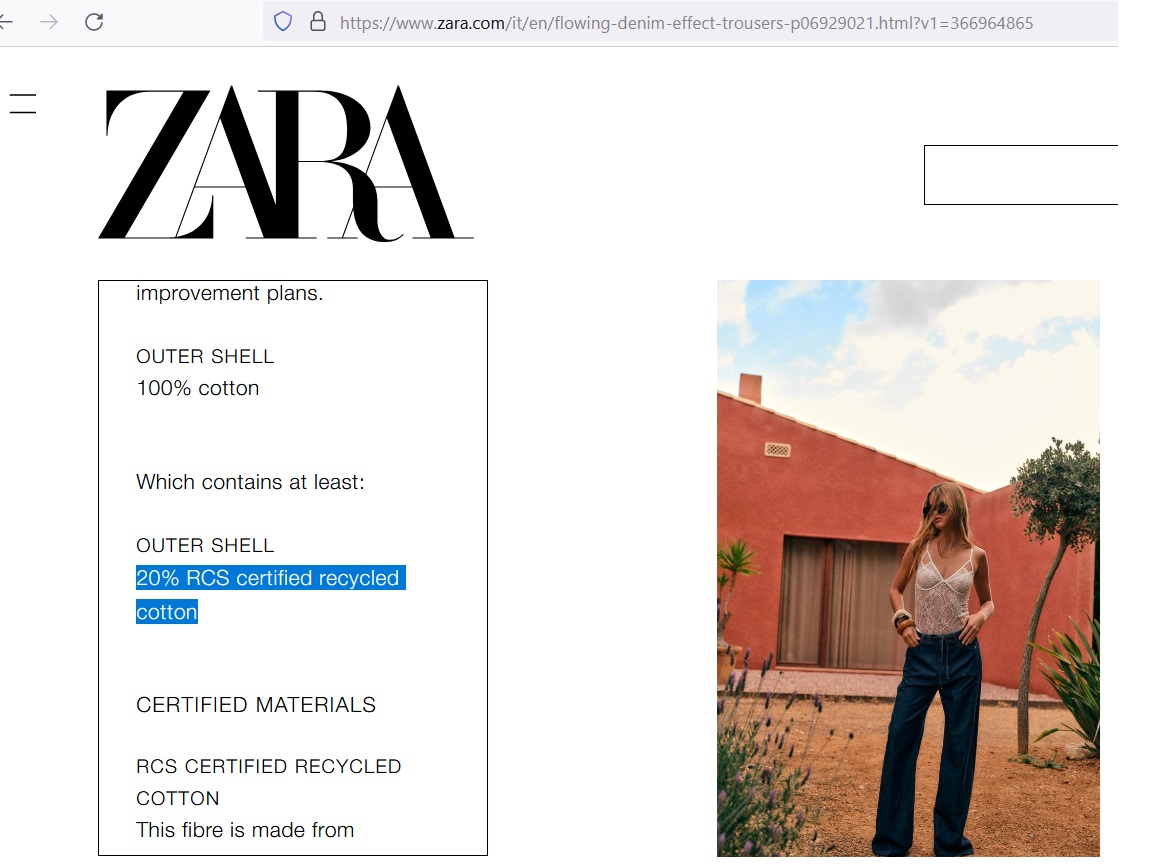

Annabelle Gensler (Fashion Merchandising & Management and Fashion Design & Product Innovation double majors): The tariff discussion has been far more impactful on my shopping habits than I would have imagined…I’d like to consider myself a thoughtful consumer in that I rarely make impulse purchases, and I do what I can to avoid feeling any sense of buyer’s remorse. This has become exceptionally true in today’s evolving state of trade policy and manifests itself in a few ways…As a fashion student, I have a good understanding of what constitutes a fair price for fashion and apparel goods. I try to use these strengths of mine by paying close attention to fiber content, care instructions, origin of materials, and manufacturing location. Overall, I’d say the tariff discussion makes me think twice, three times, ten times before making a purchase.

Alexandra Untu (Fashion Merchandising and Management and Philosophy double majors): As a fashion student and fashion lover, I closely follow tariff updates and actively try to educate myself to gain a more objective and informed perspective on the changes introduced by the current administration. Although I started shopping more consciously a while ago, I’m now more intentional than ever with my purchases…I pay attention to where clothes are made and take the time to research their country of origin and production practices. I’ve also been focusing on buying pieces made from high-quality materials, with timeless styles that are versatile enough to be worn in different outfits and settings.

Lola Kulis (Fashion merchandising and management major and 4+1 graduate student): As a Fashion Merchandising student, I’ve been especially invested in the ongoing discussion around tariffs and their impact on retail pricing. From an industry perspective, it’s scary; as someone preparing to enter the field, I feel uncertain about what the future holds. And as a consumer, I feel frustrated. We’re facing the direct impact of global trade decisions influencing the pricing and accessibility of apparel. The worst part is the uncertainty. The constant policy changes and back and forth are only putting more stress on business owners, consumers, the working class, etc.. The media coverage surrounding these trade policies has made me realize how interconnected global sourcing and retail pricing really are. I’ve started paying closer attention to where garments are manufactured and how those origins might impact cost, availability, and even quality. I’ve shifted my perspective, not only as a student but also as a consumer.

Madison Toth (Fashion Merchandising and Management major): The tariff discussion in the media has definitely increased my interest in where exactly my clothing is being made. As I shop, I have started to check labels on where these apparel items are being manufactured. It is fascinating to me that the most popular and successful U.S retailers are globally sourcing apparel, yet the increase in tariffs is being thrown into policy. Admittedly, I struggle to keep up with the news, but I’m very intrigued by the current tariff discussion. I follow closely because it will affect my job in the future as I enter my career in the fashion industry, but also as a consumer.

Price hikes and reduced product availability due to tariffs concern Gen Z consumers

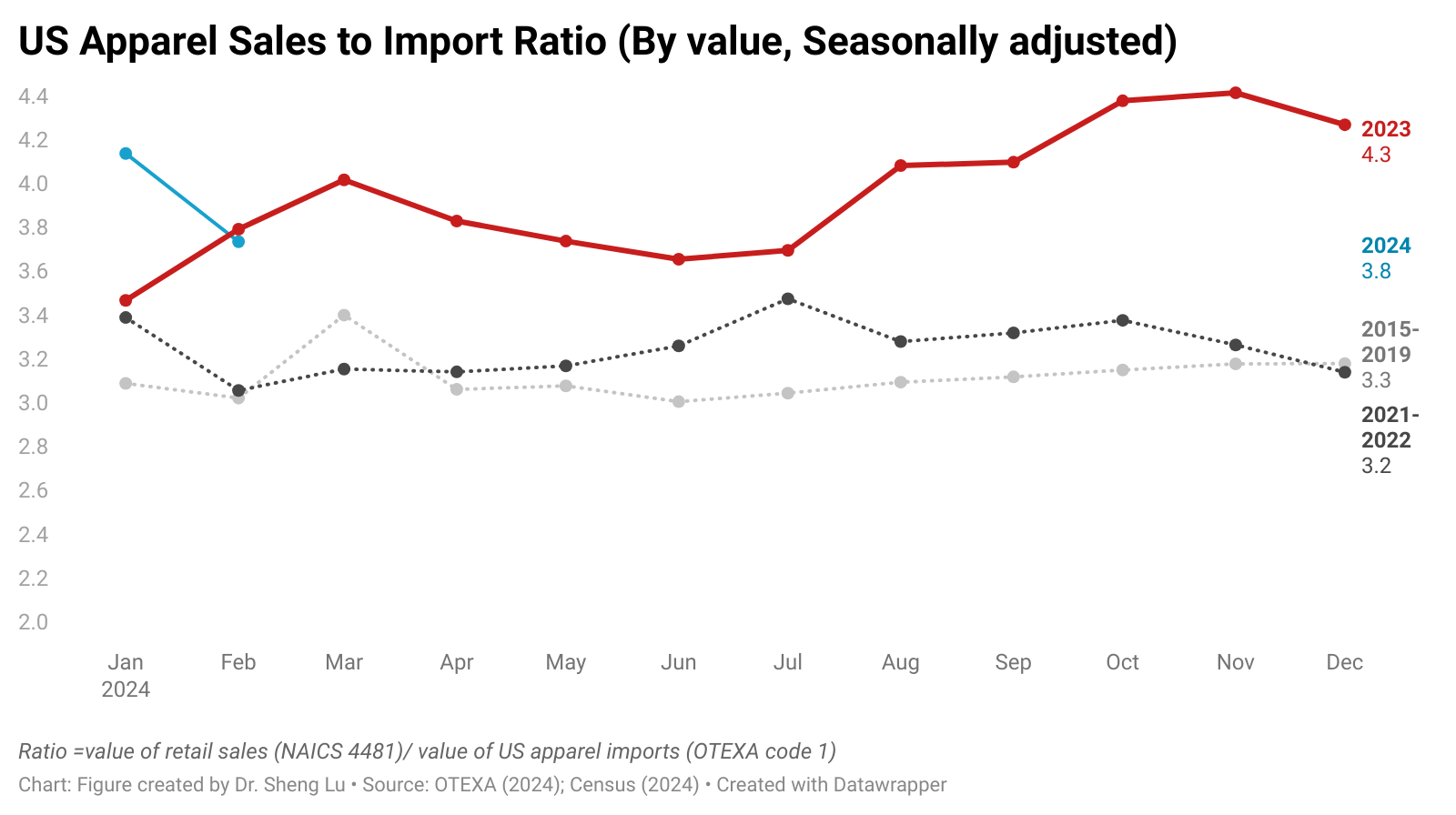

Rachel Zemel (Fashion Merchandising and Management major): Since April, I’ve definitely noticed price increases…I’ve also noticed a shift in product availability, especially when I shop online. Certain sizes and styles are gone faster than usual and don’t seem to get restocked. In stores, the selection feels limited too. It seems like brands are being more careful with how much they’re producing, maybe to avoid excess inventory or reduce risk. As someone who shops a lot and also studies this industry, it’s interesting to see how these challenges are playing out in real-time. It makes me think differently about what goes into every piece I buy.

Annabelle Gensler (Fashion Merchandising & Management and Fashion Design & Product Innovation double majors): The majority of the shopping I’ve done since April has occurred online, and the biggest difference I’ve noticed since the tariff discourse has started, is the stock of goods available. It’s rare that I stumble upon a product offering that has all sizes and colors in-stock. Now, when I filter my search for a graduation dress in the size and color I prefer, fewer and fewer items populate. In the past, retailers might have been able to bulk order goods to maintain stock domestically, or ship from international locations directly to the consumer; tariffs have halted these practices. Items I’m considering purchasing no longer feel safe in my cart because of how quickly stockouts are occurring. This, paired with an expectation of drastic increases in price, has created an internal sense of urgency when I have items in my cart. I know it’s unlikely that the item will be available at a certain price point, or at all, and so the conscious consumerism I try to practice is really being put to the test.

Alexandra Untu (Fashion Merchandising and Management and Philosophy double majors): Based on my own and my friends’ experience, the changes have been subtle so far, but noticeable. Prices have been going up gradually across all types of products, including clothing, but the availability of products hasn’t yet turned into a cause for concern. While the current situation is not dramatic as of now, there is undoubtedly a change that is happening, and we are expecting more striking changes in the near future that could affect our shopping behavior quite significantly.

Madeline Osbourn (Fashion Merchandising and Management major): The tariff increase has affected merchandise orders for my sorority. The tariffs have made the prices rise on orders that we planned on making. This creates an issue with prepaid and future orders, keeping in mind the members’ willingness to transition and conform to the higher-priced merchandise that is designed.

Lola Kulis (Fashion merchandising and management major and 4+1 graduate student): Because inflation has been on the rise for some time now, it’s hard to differentiate the cause of these price changes. Prices for basics, like denim, cotton tops, and even activewear, are outrageously high. Over the past year, I’ve observed a significant decline in promotional activity. Retailers are offering fewer discounts, and even Black Friday, once known for major deals, felt noticeably underwhelming. Considering the current global trade and policy changes, I only see this worsening. On the availability side, popular sizes and color options tend to sell out much more quickly, leading to a more competitive shopping experience.

Madison Toth (Fashion Merchandising and Management major): To be honest, I have been reluctant to shop with popular fashion retailers because of the current tariff discussions. I have strayed away from shopping online and in-store due to the uncertainty of the economic climate. While apparel prices are increasing, as well as other products, it is vital for me to take all of that into consideration. Tariffs affect more than apparel, and as a college student, some purchases take priority over clothing. Because of this, I am unable to comment on price and product availability since the tariff discussion began. I have simply decided that, for me personally, in the current economic climate, apparel shopping should be placed on the back burner.

Sustainability matters even more

Rachel Zemel (Fashion Merchandising and Management major): Sustainability matters even more to me now. When prices go up, it forces me to think about the long-term value of what I’m buying. I want to spend my money on items that are made with quality materials and with people and the planet in mind. It’s hard to justify spending more on something that was cheaply made or won’t last beyond a few wears. I think price increases actually help push the conversation toward more conscious consumption. Even with a student budget, I try to prioritize brands that are transparent about their production or at least make some effort toward ethical practices. It’s not always possible to buy 100% sustainably, but I try to balance things. thrifting, supporting small designers, and not overconsuming are just a couple of changes that can have a big impact. Sustainability isn’t just about buying the “right” thing, it’s about shifting the way we shop. That mindset doesn’t go away just because prices are rising.

Alexandra Untu (Fashion Merchandising and Management and Philosophy double majors): Sustainability has always been a core value for me, and that won’t change, even if prices rise. Sustainability isn’t just a trend; it goes far beyond money – it’s a life-or-death issue. It’s a moral responsibility we have to future generations, and we shouldn’t treat it lightly or abandon it. Shopping with sustainability in mind isn’t always the easiest or the cheapest route, but it’s the right one. Now, more than ever, we should be doing -or learning to do – the right thing. Every purchase sends a message about the change we want to see. Every purchase is a small step toward a better, more responsible future for us and for our children.

Lola Kulis (Fashion merchandising and management major and 4+1 graduate student): Sustainability matters even more to me in the face of rising prices. As clothing becomes more expensive, we become more hesitant in purchasing. I think more about what I’m investing in, starting with being intentional about supporting brands that are transparent, responsible, and committed to reducing their environmental impact. I’d rather buy less and choose more wisely than spend more on items that contribute to overproduction and waste. I’ve realized more than ever that sustainability is not a trend, it’s our future. As I prepare to enter the fashion industry, it’s important that I practice what I preach and support the long-term goals.

Madison Toth (Fashion Merchandising and Management major): Sustainability is something that I do genuinely care about. When shopping, I tend to lean more towards brands that practice ethical sourcing and are more transparent about where their items come from. From my time as a student, I have learned many of the horrible outcomes of the fashion industry related to sustainability. From seeing videos of workers begging for higher wages, seeing dyes dumped into bodies of water, and looking at the incredibly tall piles of textile waste, it sticks with me both as a student and a consumer…If a price increase meant that apparel manufacturers were getting paid fair wages, I would purchase those items. However, now, due to tariffs, I am more likely to dodge popular retailers. Sustainability is very important to my generation, and I value the efforts that brands have made to become more sustainable. But it raises the question, when is a price so high that sustainability no longer matters? To that, it’s hard to say. I think it depends on the economic status of each consumer. From sustainable companies with higher prices, there are purchases that I just cannot justify paying. I do care about sustainability, but there does come a point where it becomes financially unattainable.

Katie Yasik (Fashion Design and Product Innovation major): Yes, sustainability still matters to me, even with rising prices. It’s not always easy to prioritize, especially on a student budget, but I try to make more conscious choices like buying fewer, longer-lasting pieces or shopping secondhand. I think it’s important to consider the environmental and social impact of fast fashion, and if prices are going up anyway, I’d rather invest in something that aligns with my values.

Isabella DiGiulio (Fashion merchandising and management major and 4+1 graduate student): I think that the tariffs may bring a new wave of interest in sustainability, specifically for donation-based, second-hand clothing stores. These stores will likely be able to maintain their low pricing because they do not need to account for operational expenses in apparel production. Even if there is to be a price increase, their prices may still remain relatively lower and more affordable compared to first-hand clothing brands…Furthermore, sustainable shopping doesn’t solely refer to purchasing second-hand goods or buying from brands with biodegradable fabrics or ethical labor practices. Sustainable shopping can also refer to the abstinence from shopping. With influences such as social media and fast fashion, overconsumption has become an extremely normalized practice through which many people, especially Gen Z, feel compelled to consistently refresh their wardrobes to follow trends and keep up with the ever-changing standards of style and identity.

Explore more: