Top challenges in 2026

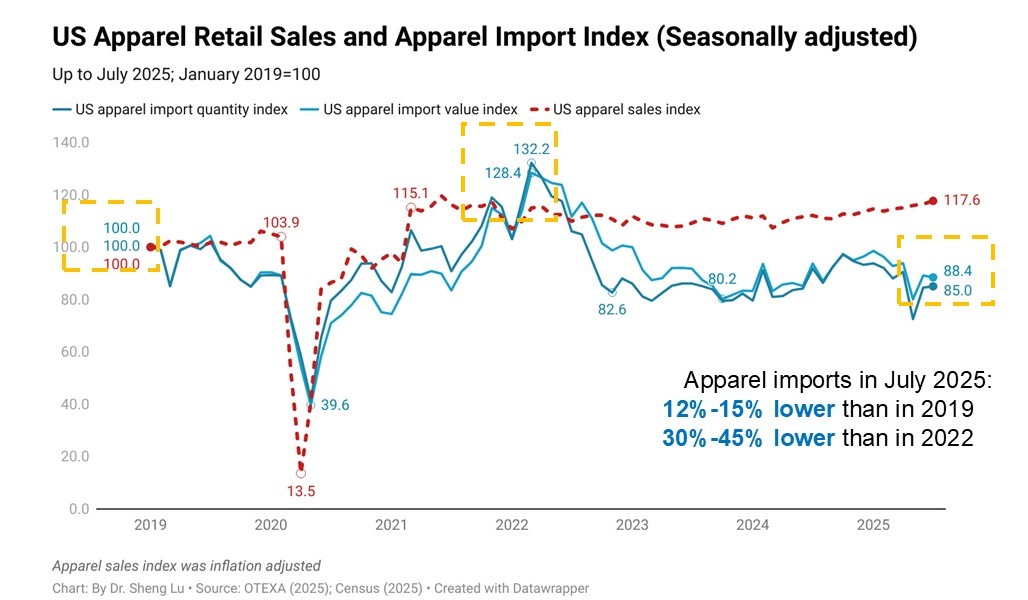

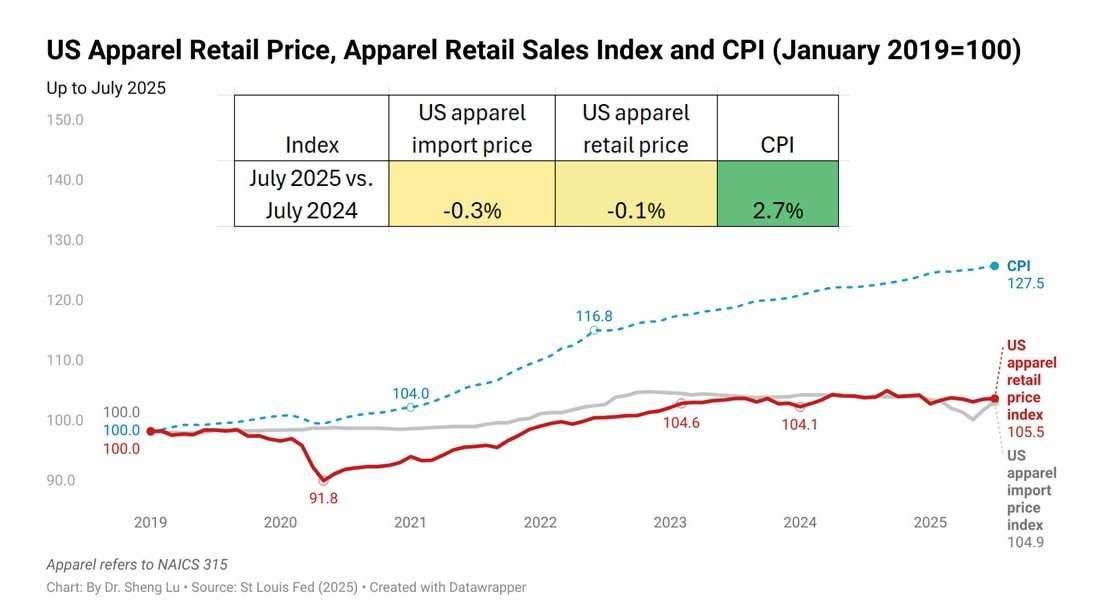

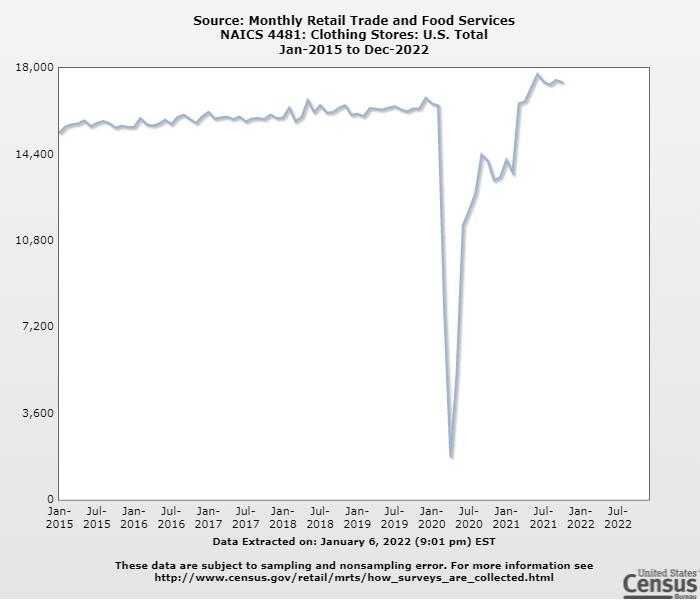

I believe the global fashion apparel industry will continue to face two macro-level challenges in 2026. One is the relatively weak consumer demand for clothing amid sluggish economic growth and persistent inflationary pressures. For example, according to the International Monetary Fund’s (IMF) October 2025 forecast, global GDP growth in 2026 is expected to decrease from 3.2% in 2025 to 3.1% in 2026. Specifically, U.S. GDP growth will be around 2.1% (down from 2.8% in 2024), and growth in the EU could drop to 1.1% (down from 1.2% in 2025).

Likewise, several consulting firms forecast that clothing retail sales in key apparel import markets, including the United States and Western Europe, could be stagnant or even decline in 2026. Notably, while Gen Z (i.e., those born between 1997 and 2012) has increasingly become a key customer group for many fashion brands and retailers, analysis shows that this generation has turned more cautious about shopping for clothing, especially for new items. The tariff-driven price increases could further discourage these groups from buying new clothing in the new year ahead.

Meanwhile, the trade policy environment facing the global fashion apparel industry could remain highly uncertain in 2026. Notably, in addition to tariffs, several trade agreements could create new uncertainties for fashion companies when sourcing from affected regions. Specifically:

The U.S.-Mexico-Canada (USMCA) trade agreement will begin its formal six-year review process in 2026. Despite broad industry support for upholding the existing agreement and calls to “do no harm,” we cannot rule out the possibility that the Trump administration might seek significant renegotiation or even replace the USMCA with separate bilateral trade deals.

Likewise, the outlook for the African Growth and Opportunity Act (AGOA) and the Haiti HELP/HOPE program, both of which expired in September 2025, remained highly uncertain. Because both programs play a critical role in supporting U.S. apparel sourcing from Sub-Saharan Africa and Haiti, whether and under which conditions they are renewed will directly influence fashion companies’ sourcing decisions and the long-term competitiveness and investment prospects of these regions.

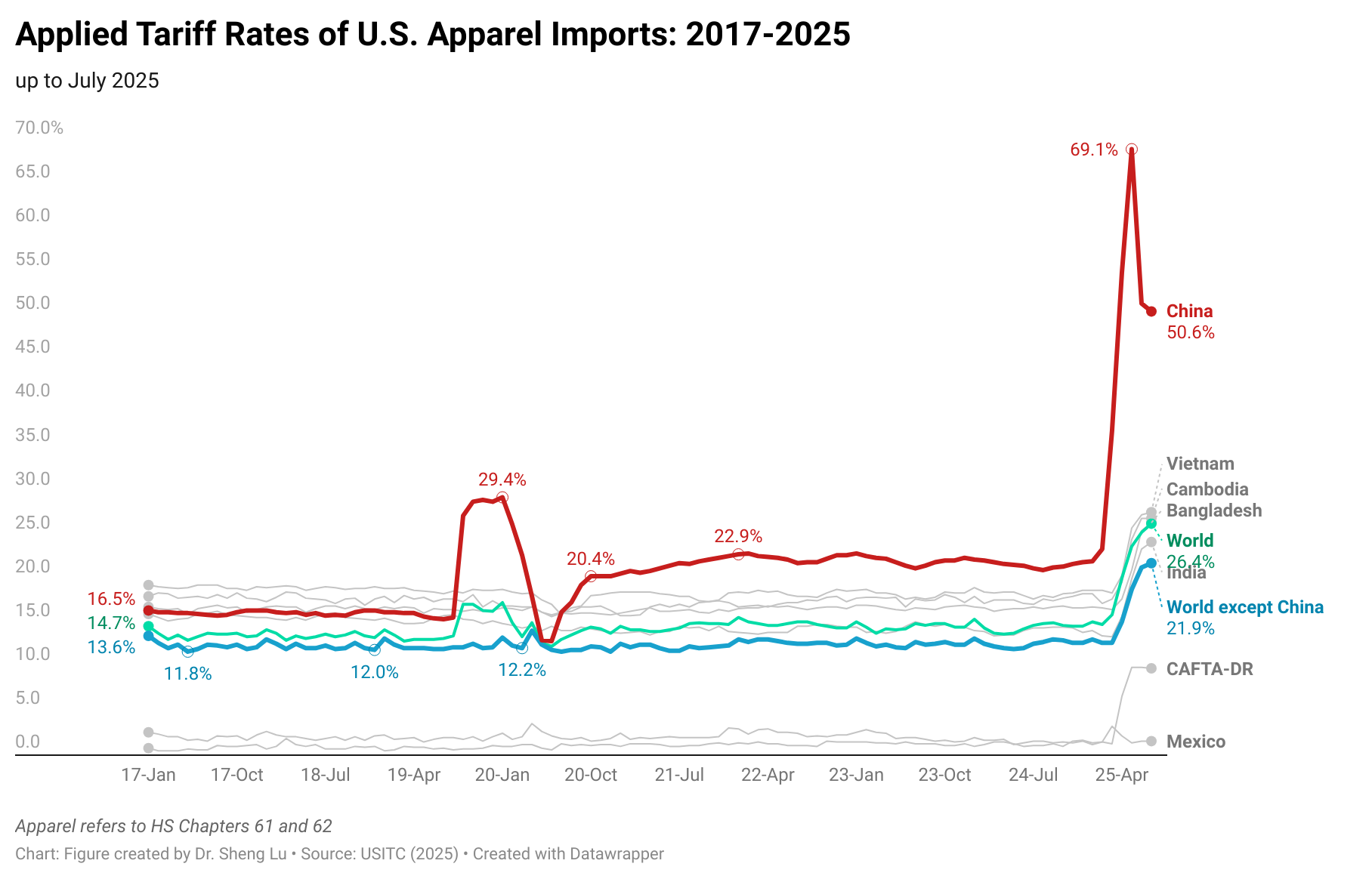

Furthermore, even with several “trade deals” reached between the US and major trading partners like the EU, Vietnam, Cambodia, and potentially China and India, their implementation and enforcement will warrant close attention. In particular, the meaning and definition of critical terms like “transshipment” in these “trade deals” remain largely unclear. However, the impact could be significant for apparel sourcing if the Trump administration ultimately decides to revisit or set new rules of origin in these agreements to reduce the “China content” in products imported into the United States. Notably, according to OECD’s newly released “trade in value-added database,” apparel exports from Asian countries, including Vietnam and Cambodia, commonly contain 20-30% of value created in China.

Key apparel sourcing trends to watch in 2026

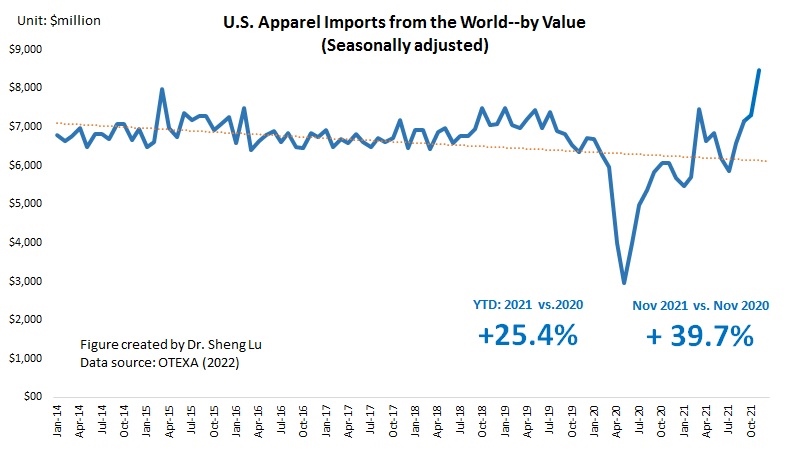

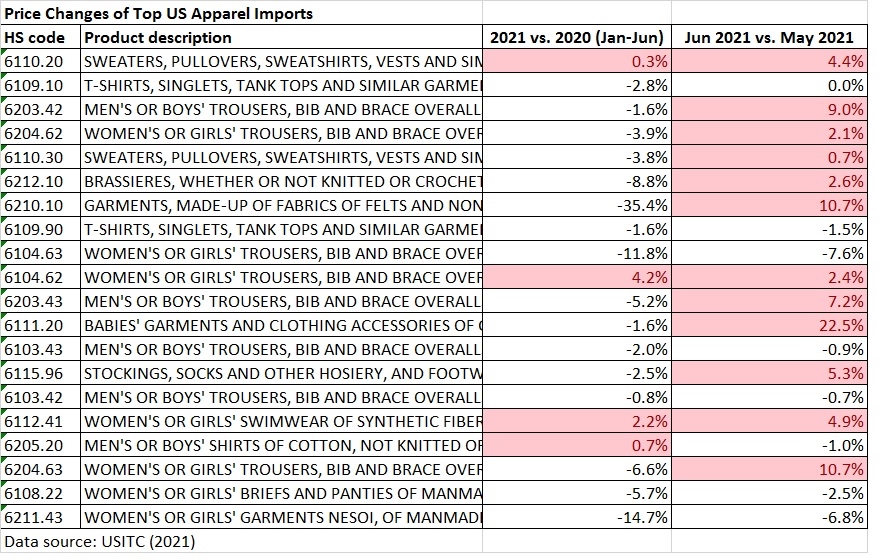

First, trade and economic impacts of tariffs could become more visible and significant in 2026. In particular, almost all U.S. apparel imports will be subject to the higher tariffs in 2026, leaving fashion companies with fewer options to use existing inventory to mitigate the effects. Consequently, fashion companies will face increased pressure to control their sourcing costs and protect their profit margins.

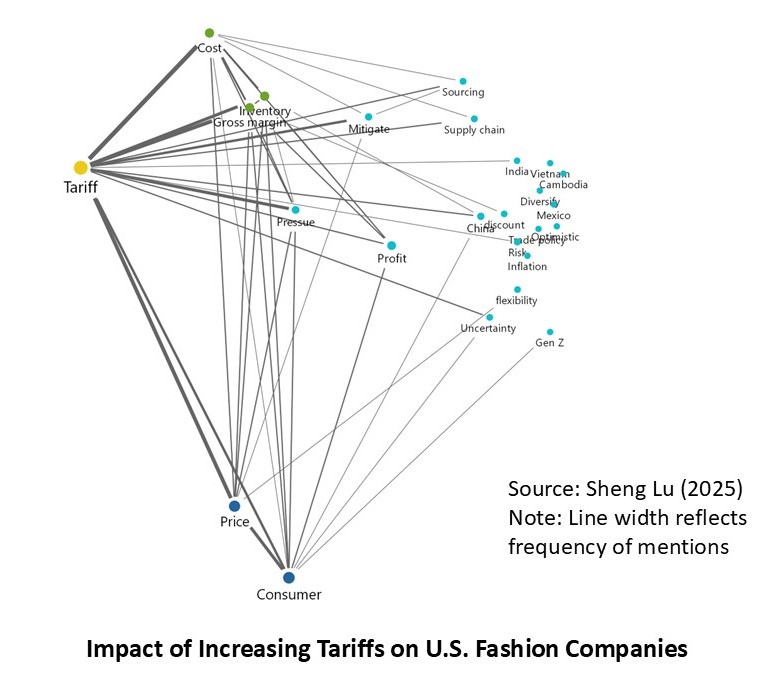

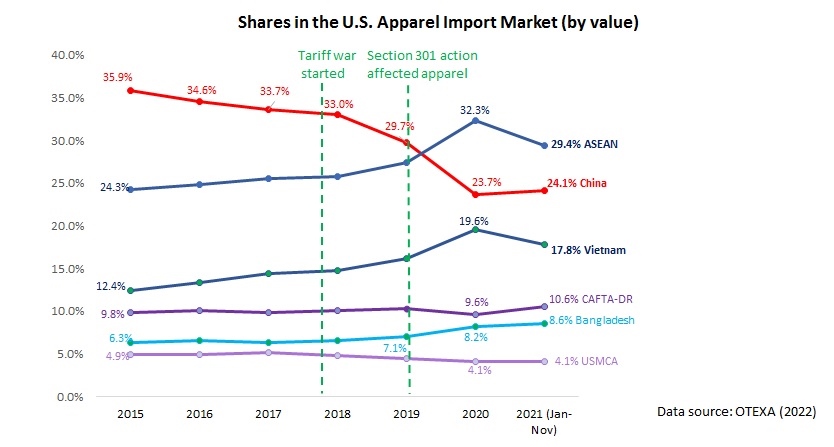

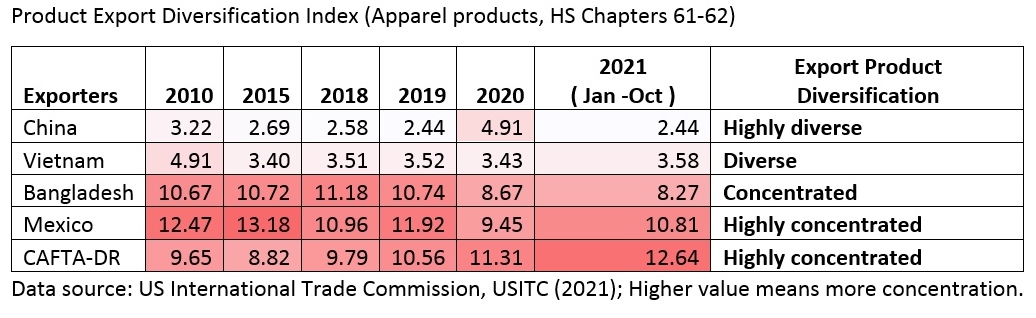

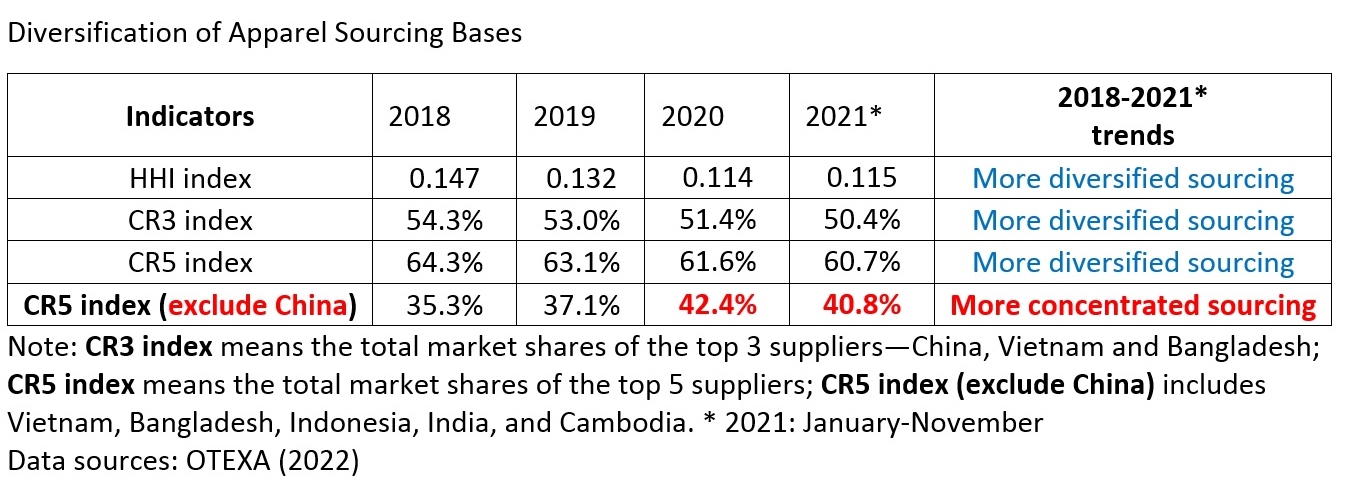

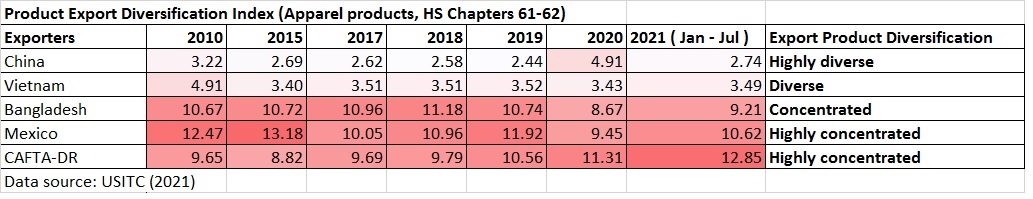

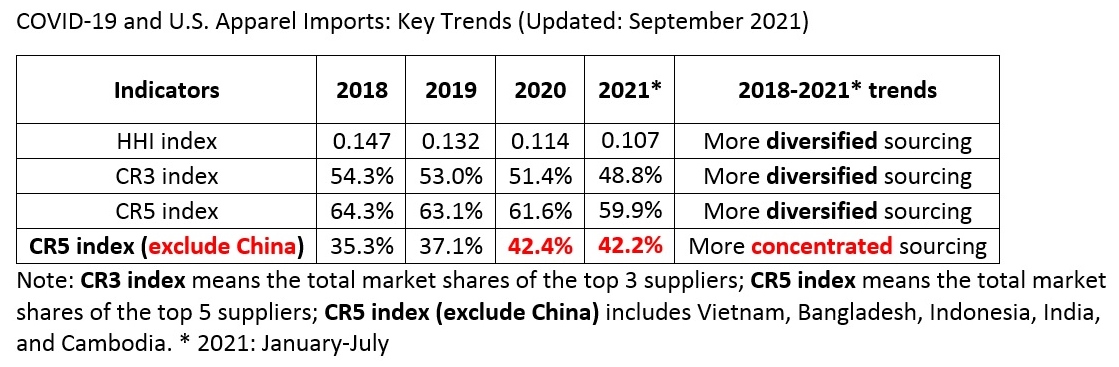

Second, fashion companies will continue to leverage sourcing diversification to navigate market and trade policy uncertainties. For example, according to the 2025 Fashion Industry Benchmarking Study released by the U.S. Fashion Industry Association (USFIA), a record-high percentage of surveyed U.S. fashion brands and retailers (i.e., over 80%) reported sourcing from 10 or more countries. Nearly 60% of respondents plan to source from even more countries in 2026. In a recent study I conducted, some leading U.S. and EU fashion companies mentioned in their 2025 Q2 earnings call transcripts that they intentionally seek vendors with production capacity across multiple countries to achieve sourcing diversification and mitigate risks.

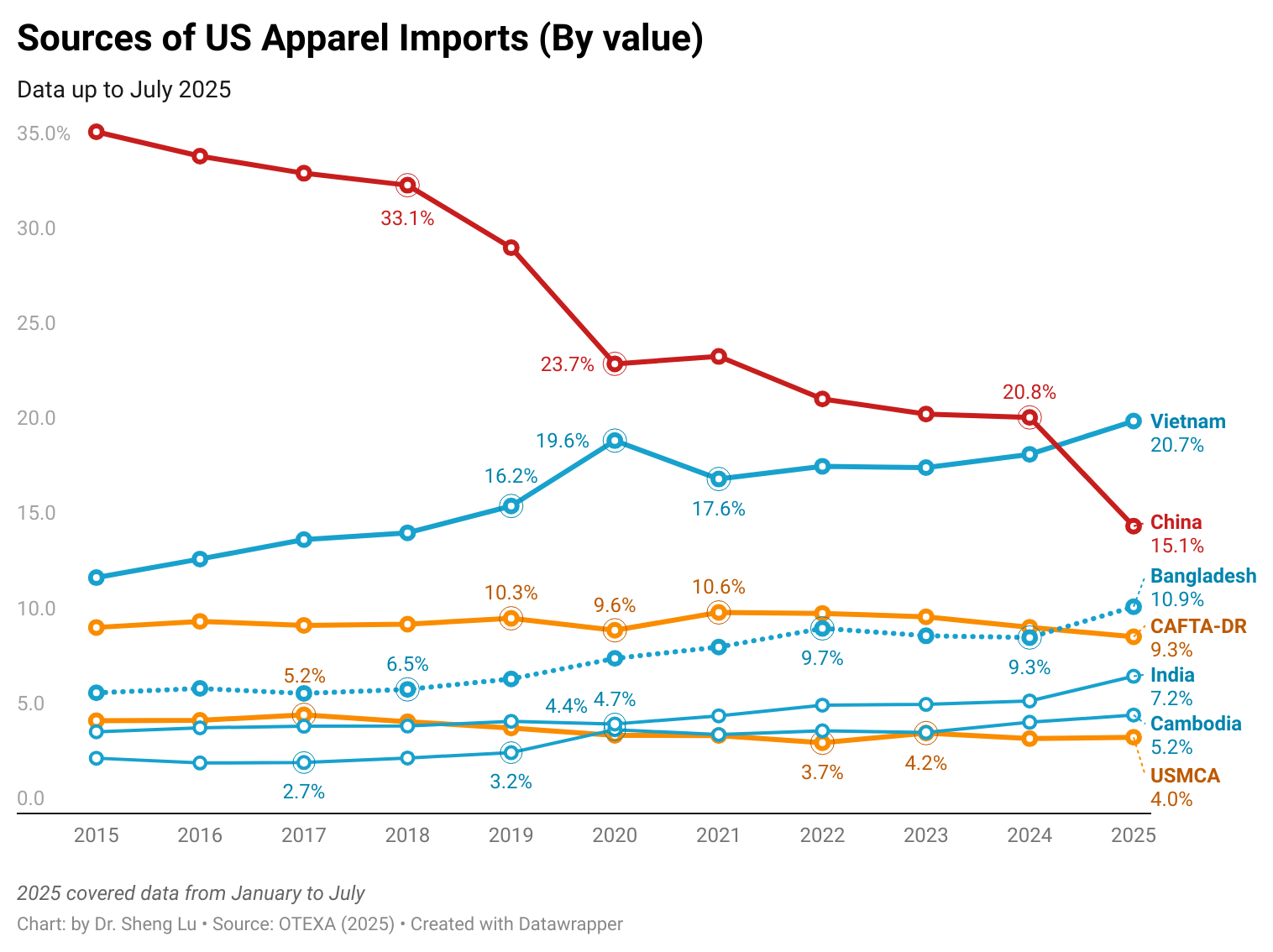

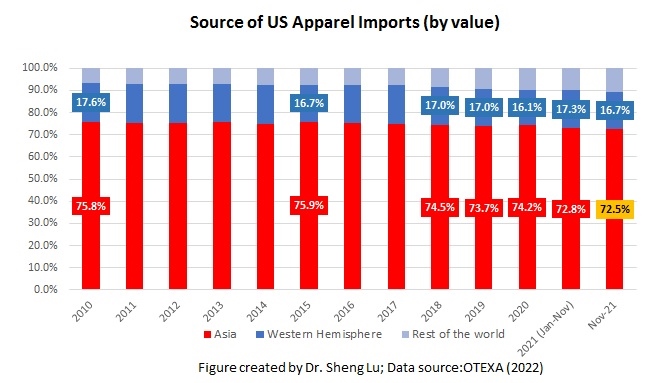

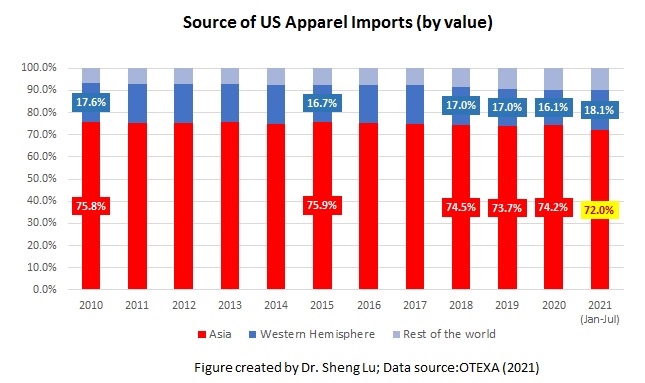

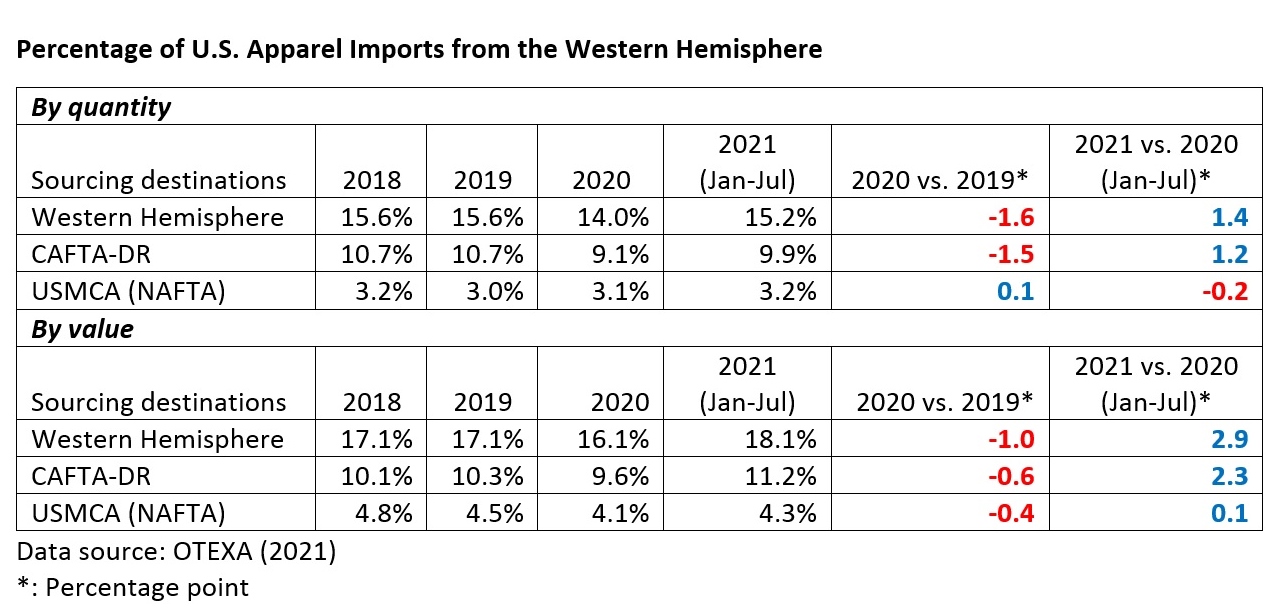

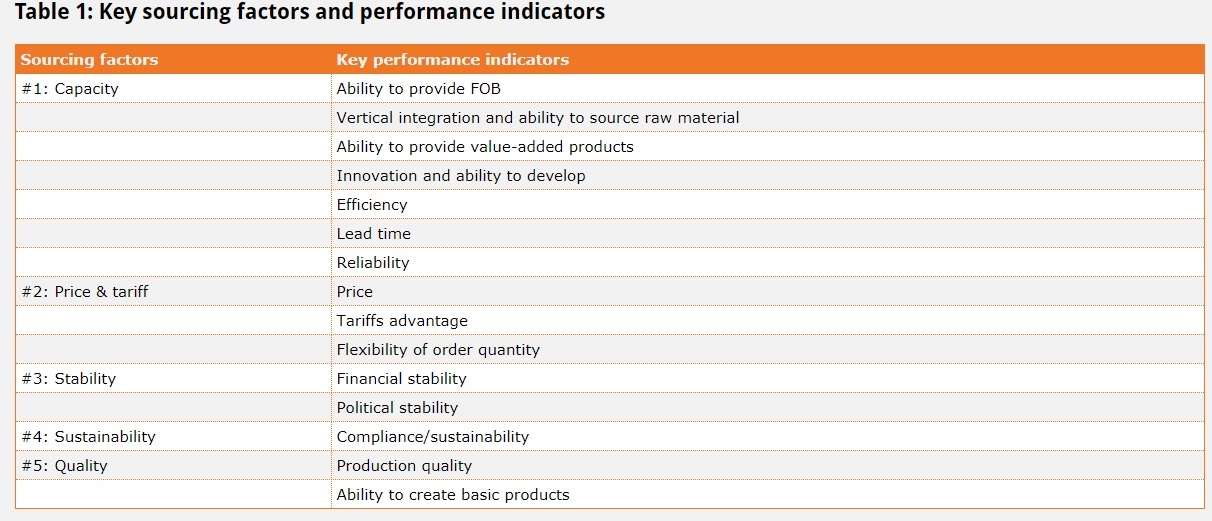

Third, in addition to seeking competitive sourcing costs, fashion companies will increasingly look for vendors that can offer speed to market, flexibility, and agility. As one leading fashion company noted, “increasing the speed” does not necessarily mean “nearshoring,” but also refers to vendors that can deliver products quickly and at scale. Meanwhile, fashion companies increasingly expect suppliers to accommodate last-minute order changes, accept low minimum order quantities (MOQs), arrange raw material sourcing, and offer other value-added services. This shows why, based on trade data, Asian suppliers overall are more competitive and have captured more market share in the U.S. and EU markets in 2025 than “near-shoring” suppliers.

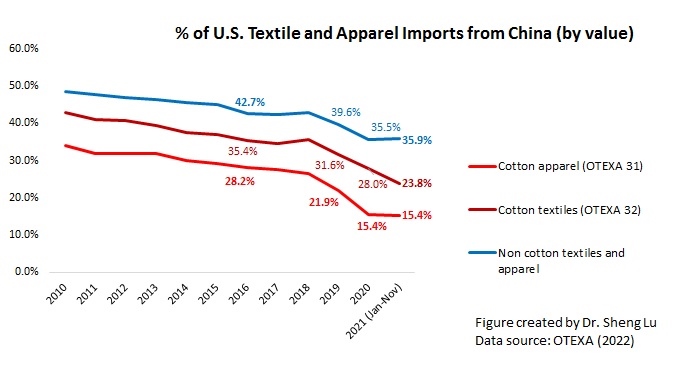

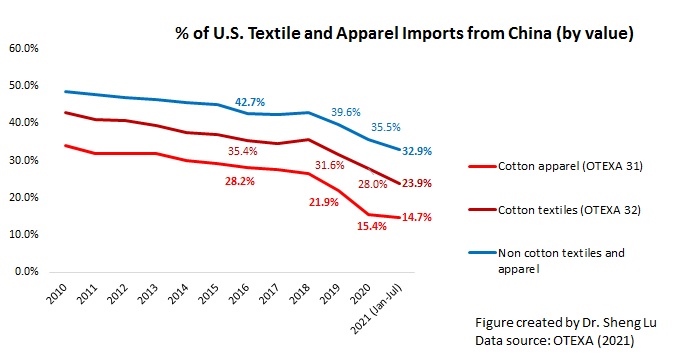

Additionally, China and Asia’s role in apparel sourcing could continue to evolve in 2026. I recently attended an industry event featuring textile and apparel manufacturers in Southeast Asian countries (ASEAN) and China. A few observations from the event stood out to me.

- While the tariff was a top concern for most U.S. fashion companies, the conference mainly focused on facilitating investment and creating a more integrated, resilient, and sustainable textile and apparel supply chain in Asia. In other words, Asia-based textile and apparel suppliers did not seem panicked by the tariffs, nor do they believe the tariffs fundamentally challenge their long-term growth trajectory or hurt their export competitiveness.

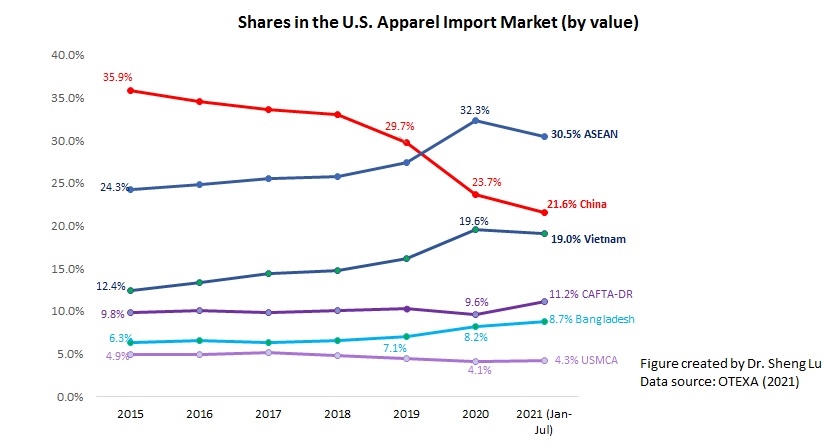

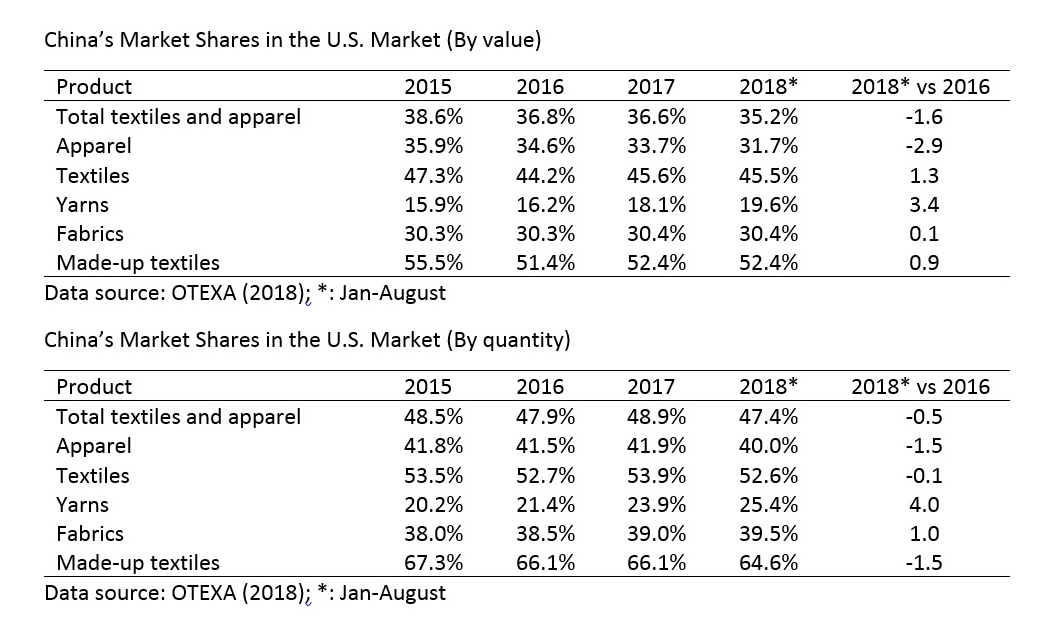

- The Asia-based textile and apparel industry is becoming ever more global, mature, and advanced. Consistent with recent trade data, Asia-based fashion brands today commonly conduct global sourcing. They are investing heavily in new sustainable textile materials and digital technologies. They remain the largest buyer of the most sophisticated textile machinery in the world. Therefore, it is reasonable to expect that Asian suppliers as a whole will continue to dominate textile and apparel production and export into 2026 with no near competitors.

- China’s leadership and influence within the Asia-based textile and apparel supply chain are increasingly visible. At the conference, ASEAN-based textile and apparel associations see China as a vital partner and source of investment. Through China’s Belt and Road Initiative (BRI), collaboration is extending from trade and investment to education and skills training. Overall, industry sentiment toward China in ASEAN differs significantly from the “decoupling” and “reducing China exposure” narratives that are gaining traction in the United States.

- An interesting question that I took away from the conference was whether China truly worries about losing market share in the U.S. and other markets for final apparel products. Perhaps not. Chinese industry leaders appear confident because they know that many Asian garment-producing countries remain heavily dependent on Chinese textile inputs, and many garment factories are funded or owned by Chinese investors. Given these dynamics, it will be interesting to observe how China’s confidence and its broader leadership role in Asia’s regional textile and apparel supply chain will continue to grow in 2026.

Opportunities in 2026

In 2026, we may see a significant increase in AI use in apparel sourcing. For example, fashion companies could use new AI tools to help optimize inventory levels and logistics, identify and evaluate new suppliers, and improve operational efficiency. AI may also play a more crucial role in supporting efforts around supply chain mapping, traceability, and sustainability data collection. Overall, we could see a more digitalized and data-driven sourcing process in the new year ahead.

On the other hand, in 2026, fashion companies could benefit from investing in and exploring new business models that support designing, making, sourcing, and selling sustainable apparel products. For example, a recent study of mine found that, by stock keeping units (SKUs) count, the number of clothing items made with recycled textile fibers increased by about 24% from 2024 to 2025 (August to October) in the U.S. retail market. Similarly, clothing items made with “regenerative” textile fibers surged by nearly 90% over the same period. These figures represent consumers’ increasing demand and fashion companies’ growing business interest in offering these products. New sustainability legislation, such as the Extended Producer Responsibility (EPR) at the state, regional, or international levels, will also create new incentives and pressure for fashion companies to revisit many of their current business practices. That said, balancing the sustainability benefits with other key sourcing metrics, such as costs, quality, and traceability, for these sustainable apparel products, will require ongoing efforts and improvements by fashion companies and their supply chain partners in 2026.

by Sheng Lu