The Bureau of Industry and Security (BIS) under the U.S. Department of Commerce recently released its assessment report of the U.S. textile and apparel (T&A) manufacturing sector. The report was based on a survey of 571 U.S. T&A manufacturers in summer 2017. These respondents include 230 textile mills (NAICS 313), 128 textile product mills (NAICS 314), and 213 apparel manufacturers (NAICS 315).

Below are the key findings of the study:

The state of the U.S. textile and apparel (T&A) manufacturing sector

- U.S. T&A manufacturing has shrunk significantly: the value of T&A shipments (seasonally adjusted) in 2016 ($68 billion) was almost 56% decrease in real terms since 1995 ($153 billion).

- U.S. T&A manufacturing has undergone substantial structural change: textiles and textile products accounted for 82% of the total shipments of the U.S. T&A industry as of 2016, compared to 57% in 1995. Notably, only 18% of shipments came from apparel manufacturing in 2016, compared to 43% in 1995.

- U.S. T&A manufacturing sector is hiring less: Between 1990 and 2016, total employment decreased by 79%, from 1.7 million to 352,000 workers; over the same period, over 86% of apparel manufacturing jobs disappeared.

- U.S. T&A manufacturers are making more capital investments: The overall total Capital Expenditures (CAPEX) of the 571 respondents increased 90 percent from 2012 to 2016 (from $1.6 billion to $3.1 billion). Particularly, the CAPEX of textile mills grew by 80 percent over that period—mostly on “Machinery, Equipment, and Vehicles.”

- North Carolina hosted the largest number of U.S. T&A facilities (22 percent of the respondents), followed by Georgia (10 percent), and South Carolina (9 percent).

- China, Mexico, and Canada are the most popular destinations for foreign investments by U.S. T&A manufacturers.

Competition landscape and factors

- Respondents listed a total of 1,309 U.S. competitors and 552 non-U.S. competitors. Chinese companies were cited as the number one source of foreign competition.

- “Quality,” “Lead Time,” and “Innovation” were the top three competitive advantages of U.S. T&A manufacturers as they related to foreign competition. “Labor Costs” was regarded as the top disadvantage of U.S. T&A manufacturing.

- 43 percent of respondents believed that reshoring was occurring in U.S. T&A manufacturing. Almost all of these respondents believed that “Shorter Lead Times” and the “Marketability of the ‘Made in USA’ Label” were the factors driving the trend.

- The Affordable Care Act (ACA), Minimum Wage regulations (Federal, State, and Local), and U.S. Trade Policy were the top governmental regulations and provisions cited as negatively impacting the competitiveness of U.S. T&A manufacturers.

- 61 percent of respondents reported that they had difficulties hiring and/or retaining employees for their T&A operations, specifically production line workers such as operators and machine technicians. The skill gaps in the labor market for those positions were by far the biggest ones identified for the industry.

- 43 percent of respondents believed that reshoring was occurring in T&A manufacturing (i.e., the practice of transferring a business operation that was moved to a non-U.S. location back to the United States.) Textile manufacturers were more likely to be aware of reshoring.

Trade and U.S. textile and apparel manufacturing

- On average, respondents say 48 percent of their textile and textile products are “100 percent made in the U.S.”, while for apparel it was around 54 percent.

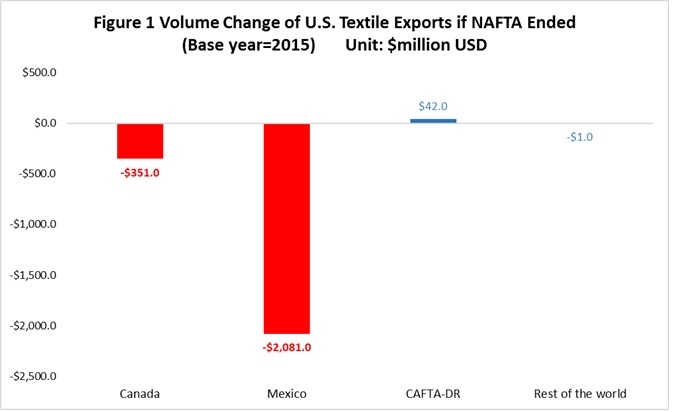

- U.S. T&A exports dropped 10 percent between 2012 and 2016, from $2.2 billion to $1.98 billion. On average, exports accounted for only 12 percent of respondents’ total sales.

- 33 percent of respondents considered themselves to be dependent on foreign sources for supplies, which was highest among textile mills.

- 37 percent of respondents reported that they considered themselves to be dependent on non-U.S. sourcing for their machinery or equipment.

Berry Amendment and U.S. textile and apparel manufacturing

- For textile mills, an average of 12 percent of U.S. output was Berry Amendment-related; for textile product mills the average was 21 percent, and for apparel production, it averaged 26 percent. 67 percent of respondents believed that the Berry Amendment had a positive impact on their organization’s business.