The latest Just-Style State of Sourcing Survey suggests a few trends of apparel sourcing in 2018:

First, apparel companies are attaching greater importance to speed-to-market in their sourcing decisions. According to the result, the need for a faster, more responsive supply chain is being driven by consumers’ increasing demands for immediacy and constant newness, as well as the speed with which social media can spread new trends.

Second, respondents say the rising sourcing and production cost remains one of their top business challenges in the New Year. Key drivers of cost increase include wage of production workers, raw material price and the social and environmental compliance cost. Notably, almost half expect their sourcing budget to go up, with 15.3% seeing an increase of more than 5%, and 32.8% anticipating a rise of between 1% and 5%. A further 32.1% see their budgets staying the same in the year ahead.

Third, the survey result confirms that China’s dominance of global apparel manufacturing is unlikely to change anytime soon. Asked about their China sourcing plans in 2018, 21.1% of respondents said they would buy more here over the next 12 months, some 30.5% expect their China sourcing to remain roughly the same year-on-year, and 28.9% expect to source less. Respondents say that “no other country can match China regarding the size of its supply base, its range of skills, its quality levels, its product variety and the completeness of its supply chain. The country also continues to lead the way when it comes to efficiency and infrastructure.” Meanwhile, Bangladesh and Vietnam continue to be seen as the two sourcing markets most likely to grow in importance in the next five years.

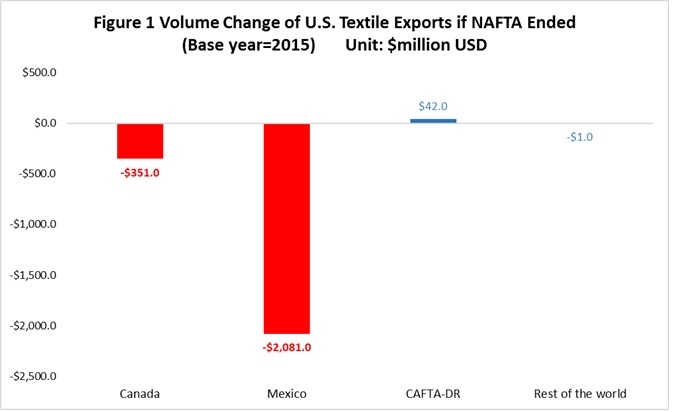

Fourth, respondents also expressed concerns about uncertainty over trade agreements (64.5%), particularly how the Trump Administration may do with the North American Free Trade Agreement (NAFTA). However, the impact of uncertainty created by Brexit seems to be limited.